Evonik's VESTALITE S curing agents win automotive award

Evonik’s epoxy hardener for use in SMCs for automotive applications won IALTA’s 2019 Automotive Lightweight Green Technology Award.

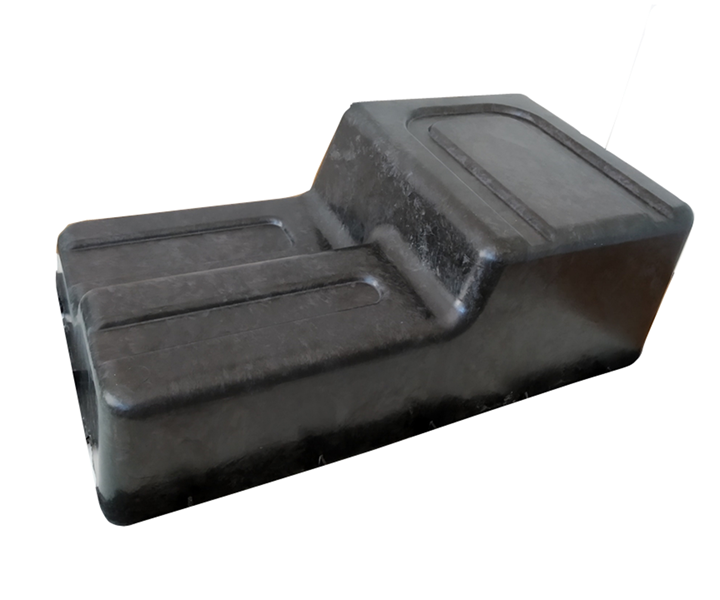

Battery case based on VESTALITE S. Source | Evonik

Evonik (Parsippany, N.J., U.S.) announced on Jan. 7 that its Crosslinkers Business Line has received award recognition from the International GREEN Auto Lightweight Technology Alliance (IALTA) for its VESTALITE S epoxy hardener for use with sheet molding compounds (SMC).

With the annual Automotive Lightweight Green Technology Award, IALTA recognizes technologically innovative companies that have made outstanding contributions to the development of innovative international automotive lightweight and green technology applications. The award recognizes technologies that are significantly beneficial for vehicle energy-saving, emission-reduction and safety as well as the application of lightweight vehicle material. The 2019 award was presented to Evonik at an event in Hefei, China in December 2019.

Evonik’s VESTALITE S curing agents have been developed for use with epoxy SMC materials in automotive applications, designed to meet increasingly stringent requirements for both lightweight design and vehicle indoor air quality. VESTALITE S is said to improve the technical properties and workability of high-performance SMCs for use in e-mobility applications and automotive lightweight construction.

“VESTALITE S curing agents in combination with epoxy resins result in SMC materials that are quick and easy to process for structural lightweight applications with minimal emission values,” says Dr.-Ing. Leif Ickert, who is responsible for marketing of composites and adhesives in Evonik’s Crosslinkers business line.

Related Content

-

Henkel releases digital tool for end-to-end product transparency

Quick and comprehensive carbon footprint reporting for about 58,000 of Henkel’s adhesives, sealants and functional coatings has been certified by TÜV Rheinland.

-

Performance resins, putties and structural adhesives

CAMX 2025: Scott Bader illustrates its local and global materials supply availability backed by technical support, as well as a novel composite panels development with Armacell.

-

IPS Adhesives debuts Scigrip SG2000 adhesive in North America

The adhesive’s 1:1 mix ratio and long open time provides transportation, construction and marine industries with much-needed routine simplification and flexibility.

.jpg;width=70;height=70;mode=crop)