Dieffenbacher Fiberforge system contributes to South Korean UNIST research

Ordered from Dieffenbacher in 2019, the tape laying system has enabled the advancement of research for companies in the automotive and aerospace industries.

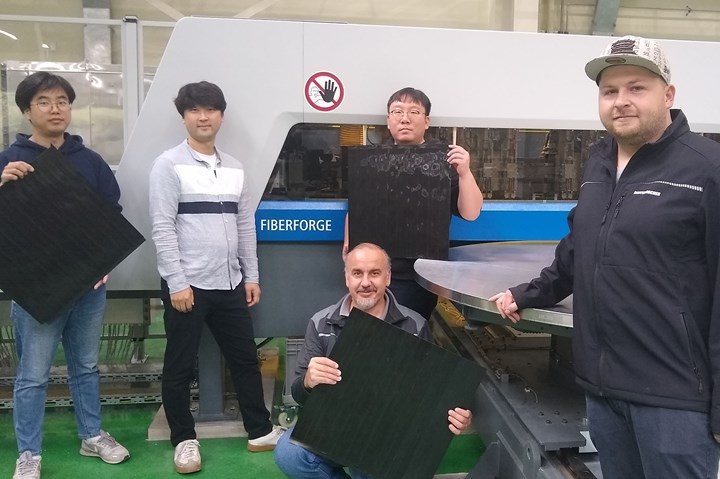

The UNIST team. Photo Credit: Dieffenbacher

A Fiberforge tape laying system from (Eppingen, Germany) — which manufactures near-net-shape laminates from continuous fiber-reinforced glass or carbon fiber tapes — is helping the South Korea Ulsan National Institute of Science and Technology (UNIST) advance its research for companies in the automotive and aerospace industries.

Accepted and in use since mid-October 2020, the tape laying system ordered by UNIST in 2019 was the first Fiberforge order for Dieffenbacher in this region. Installation and commissioning of the tape laying system began in August 2020.

“We develop new processes and applications, mainly for companies in the automotive and aerospace industries,” says Prof. Young-Bin Park, head of the UNIST Composites Research Center. “We were looking for a highly precise and economical tape laying system and found it at Dieffenbacher. Fiberforge takes our research to a whole new level.

“Despite the COVID-19 pandemic, which initially caused a slight delay in the start of construction work, the rest of the project went absolutely smoothly,” he adds. “Many thanks to the entire Dieffenbacher team for the fast and uncomplicated installation and commissioning despite the difficult conditions.”

According to Dieffenbacher, the UNIST project underscores the versatility of the Fiberforge technology. Said to be the world’s fastest tape laying system, the company says the technology is suitable for both the mass production of lightweight components and research for new processes. More than 10 systems are in use in production worldwide. In addition to UNIST, seven other research institutes are equipped with Fiberforge technology.

Related Content

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.