Desktop 3D printing companies MakerBot and Ultimaker agree to merger

The new entity will maintain headquarters in New York, U.S. and the Netherlands, with respective CEOs serving as co-CEOs.

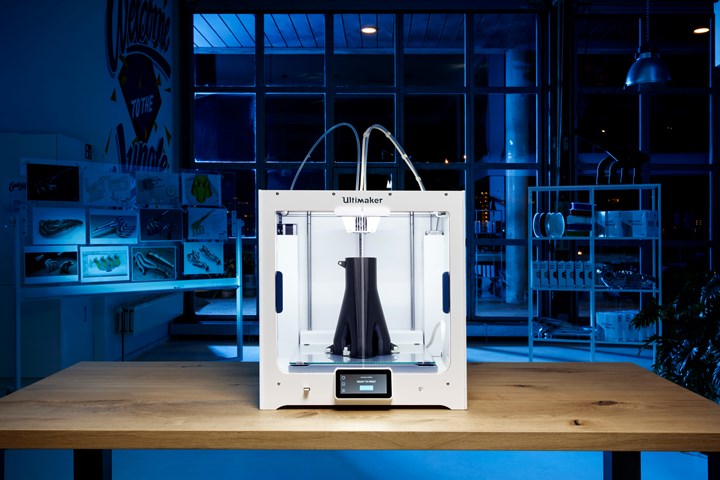

Ultimaker S5 printer.

Photo Credit: Ultimaker

Desktop 3D printing companies (Brooklyn, N.Y., U.S.) and (Utrecht, Netherlands) announced on May 12 that they will merge as one entity, with the goal of accelerating the adoption of additive manufacturing by providing a comprehensive desktop 3D printing ecosystem of hardware, software and materials.

The new entity will be backed by existing investors, NPM Capital and Stratasys (Eden Prairie, Minn., U.S.), and will benefit from a planned cash investment of $62.4 million to fuel innovation and expansion into new markets.

The new company will be led by Nadav Goshen, current MakerBot CEO, and Jürgen von Hollen, current Ultimaker CEO, who will act as co-CEOs, with Goshen managing operations and R&D and von Hollen managing the commercial functions.

“This merger marks an important milestone for Ultimaker and MakerBot,” says von Hollen. “Innovation and growth are both critical to bringing desktop 3D printing from a specialty technology into mainstream business adoption. The new company will leverage and expand its combined global footprint with sales and operations in the Americas, EMEA and APAC.”

“Technological innovation is paramount in growing the availability of easy-to-use professional 3D printing solutions,” says Goshen. “By combining our teams and leveraging the additional funding, we can accelerate the development of advanced solutions to provide our customers with a broad portfolio of hardware and software solutions to serve a wide spectrum of customers and applications."

The new entity aims to offer easy-to-use and accessible desktop 3D printing solutions for any application while inspiring the industry to a future state of responsible and sustainable manufacturing.

The new company will maintain headquarters in both the Netherlands and New York, U.S. The transaction is subject to consultation of appropriate employee representative bodies and regulatory approvals, with closing currently expected over the course of the second or third quarters of 2022.

Related Content

-

Multi-material, self-sensing, 3D-printed scoliosis braces

Startup Fited and Brightlands Materials Center have developed a lighter weight, thinner CFRP corrective brace, including pressure sensors made from continuous carbon fibers.

-

Large-format AM speeds plug production for manufacture of composite boat molds

Hungarian manufacturer Rapid Prototyping transitioned its conventional foam milling process to 3D printing to produce faster, higher quality, recyclable foam plugs and composite boat molds.

-

Al Seer Marine, Abu Dhabi Maritime unveil world’s largest 3D-printed boat

Holding the new Guinness World Record at 11.98 meters, the 3D-printed composite water taxi used a CEAD Flexbot to print two hulls in less than 12 days.

.jpg;width=70;height=70;mode=crop)