Composites industry experts collaborate to address ISO 12215-5:2019 standard challenges

3A Composites Core Materials, STRUCTeam and Beneteau are working to rectify the shortcomings of core requirements of small marine craft in the 2019 framework, while exploring optimal design approaches with foam and balsa core materials.

Airex/Baltex core material offerings. Photo Credit: 3A Core Composite Materials

STRUCTeam Ltd. (Cowes, U.K.), an independent composite engineering consultancy, is collaborating with sandwich composite technology company 3A Composites Core Materials (Sins, Switzerland) to address challenges posed by the revised , which accordingly “defines the dimensions, design local pressures, mechanical properties and design stresses for the scantlings determination of monohull small craft.” This technical partnership marks an advancement in providing support for 3A Composites Core Materials’ customers and the broader marine industry, as they navigate the amended structural design guidelines for small crafts.

Sandwich core materials have been used successfully by the marine Industry for almost 60 years. Today, naval architects and boat yards want to be more sustainable, responding to cost pressures and delivering the finest products for their clients. Many want to increase their use of sandwich construction, but in most geographies, ISO compliance remains paramount for vessels less than 24 meters.

The 2019 edition supersedes ISO 12215-5:2008 and introduces more stringent core strength requirements and changes in methods to compute structural compliance. These modifications have a notable effect on flat sandwich panels, resulting in a potential increase in weight by up to 30% for hull and deck plating. Consequently, vessels that adhered to the 2008 edition may not meet the criteria of the 2019 edition, leading to what is commonly referred to as “grandfathering.”

CompoSIDE’s Yacht Designer marine scantling tool, used to achieve more comprehensive marine application designs. Photo Credit: STRUCTeam

Recognizing the importance of addressing these challenges, 3A Composites Core Materials and STRUCTeam presented their findings to Grégoire Dolto of CTN Conseil. Dolto, an engineer and naval architect with experience drafting multiple ISO standards, and convener of ISO WG 18 that drafted ISO 12215 standards from 2003-2021, further engaged Beneteau (Saint-Gilles-Croix-de-Vie, France), a sailboat builder and institutional contributor to ISO. The collaborative aim was to identify the root causes and develop solutions to prevent or alleviate this “grandfathering” effect as the ISO standard continues its evolution. The primary focus was on rectifying the shortcomings of the 2019 framework and exploring optimal design approaches with foam and balsa core materials.

Although mitigating the weight penalty within the 2019 edition is possible, it requires the allocation of extra engineering resources and budget, using finite element analysis (FEA). In response, 3A Composites Core Materials has initiated a dedicated test program aimed at enhancing material data for FEA analysis of its materials. Simultaneously, STRUCTeam and Beneteau are actively developing long-term solutions and proposals, with the goal of submitting them to the ISO Working Group.

“This joint work, with leading and recognized companies from our industry, allows us to better support our clients in professional and pragmatic compliance with the ISO 12215-5:2019 standard which drives the best choice of core material versus requirements,” notes Eric Gauthier, 3A Composites Core Materials’ CEO.

According to Nico Voorzee, STRUCTeam’s marine sales lead, the project has resulted in “a major update to our commercially available software solution, CompoSIDE, seamlessly integrating the 2019 edition of the ISO 12215-5 into our ISO compliance module, YACHTScant. This achievement further strengthens our commitment to providing industry-leading solutions.”

Related Content

Hybrid composite architecture enables rigid wind propulsion solution for maritime decarbonization

GT Wings’ AirWing leverages aerospace engineering principles combined with hybrid glass and carbon fiber composite construction to deliver up to 30% fuel savings through compact, deck-compatible wind propulsion.

Read MoreHexcel core supports Boeing’s development of the MQ-25 Stingray

HRH-302 honeycomb core material, currently under evaluation for use around the UAV’s high-temperature exhaust nozzle, could considerably extend its range.

Read MoreAirbus video highlights RACER compound helicopter first flight

Launched as part of a Clean Sky 2 program, a compound design — rotor, split fixed-wing, propulsive propellers — uses composites to cut fuel consumption and emissions by 20%.

Read MoreHyWaSand demonstrates large-series production potential for automotive TP sandwich components

Storage compartment flap for truck interior produced via fully automated continuous fiber thermoplastic sandwich molding technology shows suitability for series manufacture.

Read MoreRead Next

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

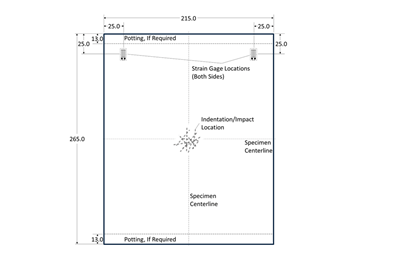

Read MoreDamage tolerance testing of sandwich composites: The sandwich CAI test

A new ASTM-standardized test method established in 2022 assesses the compression-loaded damage tolerance of sandwich composites.

Read MoreASTM composite materials standard proposals to support new infrastructure

WK83812 and D8505/D8505M standards are relevant to nonmetallic materials that are applied to concrete structures for newly built civil and infrastructure applications.

Read More