Clean Sky 2 program highlights NEWCORT and DIMES project

The projects focus on technologies that can detect pre-existing damage and improve composite repairs for next-generation aircraft.

AdaptHEAT composite repair technology. Source | Clean Sky 2

The European Union-funded program has recently reported two projects explored in its mission to reduce CO2, gas emissions and noise levels produced by aircraft. The two projects — the NEWCORT and DIMES project— respectively include a heating technology to enable better composite repairs for complex structures and a prototype measuring system to monitor the condition of aircraft.

Running from January 2016 to December 2019, the NEWCORT project focused on new heating processes and equipment for the curing of new resins for the repair of aircraft airframes (e.g., wings, fuselages and control surfaces) primarily fabricated from carbon fiber-reinforced plastic (CFRP). The of this effort was AdaptHEAT, a method that homogeneously heats and polymerizes new types of resins around complex curved structures and cures at 120-140°C.

According to the NEWCORT project, airlines and maintenance repair and overhaul centers (MROs) can use the technologies to increase the range of composite repair applications, while reducing the overall repair time requirements, especially in terms of thermal surveys and preparations.

The aim of the DIMES project is to develop and demonstrate an automated measurement system that integrates a range of measurement approaches to enable damage and crack detection. The system also monitor damage and cracks as they originate at multi-material interfaces in an aircraft assembly.

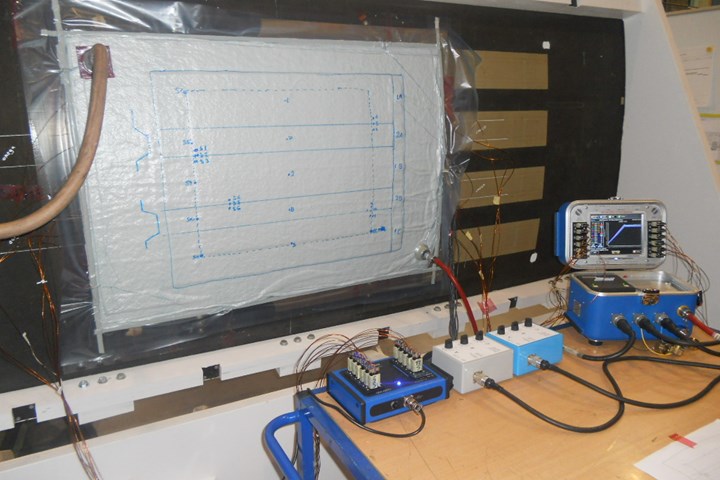

The project follows a prototype measurement system for monitoring the condition of aircraft structures that has been installed in a full-scale test rig at EMPA (Swiss Federal Laboratories for Materials Science and Technology) in Duebendorf, Switzerland. DIMES says the test rig consists of a section of an A320 wing that was delivered to the laboratories of EMPA by Airbus (Toulouse, France), the topic manager for DIMES. The wing was installed in the test-bench in early November 2019.

DIMES says the wing section installed at EMPA had pre-existing damage; the project hopes it will propagate during the test, allowing the prototype systems to track it using visible and infrared spectrum cameras, as well as electrical and optical sensors. According to DIMES, the final stage of the project will involve installing a series of the novel systems in a complete wing undergoing a structural test in the new Airbus Wing Integration Centre (AWIC) in Filton, U.K. The project is scheduled for completion in December 2020.

Visit for more information about these and other ongoing projects.

Related Content

-

Improving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

-

Damage tolerance testing of sandwich composites: The sandwich CAI test

A new ASTM-standardized test method established in 2022 assesses the compression-loaded damage tolerance of sandwich composites.

-

Active core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.