CEAD qualifies Airtech Dalhtram resins for use on all AM Flexbot platforms

Combination of the robot-based system with Airtech’s extensive resin line will enhance composites AM production and performance flexibility across multiple industries.

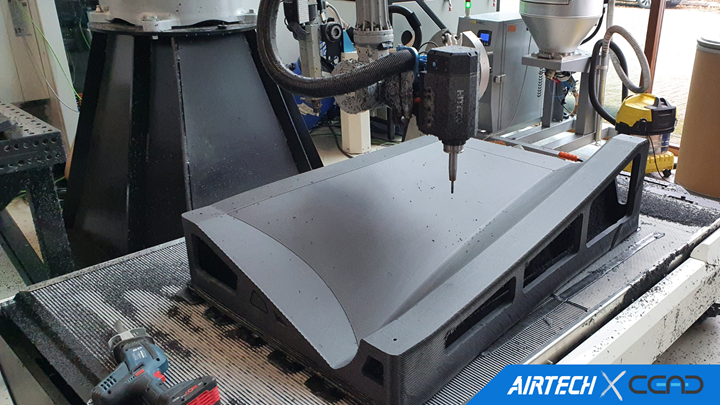

Photo Credit: Airtech, CEAD

In addition to expanded its offering of resins for use in additive manufacturing (AM) Airtech Advanced Materials Group’s (Huntington Beach, Calif., U.S.) Dalhtram resins have been qualified for use on all CEAD (Delft, Netherlands) robot-based AM Flexbot platforms. With exceptional process knowledge, application requirements and production performance, Airtech contends that this development offers breakthrough performance and unparalleled flexibility across industries.

The , one of CEAD’s solutions for large-scale composite AM, uses Comau (Turin, Italy) robots directly controlled by Siemens’ (Waltham, Mass., U.S.) Sinumerik operating system. It offers the option to combine 3D printing and milling into one automated process and provides multiple options which can be integrated to configure the system to specific needs. This versatility makes it ideal for moldmaking and tooling applications, for example, when needing to achieve a required surface finish.

Airtech Dahltram resins are suitable for multiple print platforms, offering production flexibility with end-use material validation. Airtech reports that it has continued to demonstrate efficacy in composites fabrication with extensive autoclave cycle testing across various platforms with all materials offered. Providing extensive mechanical characterization data, Dahltram resins are well suited for composites fabrication, as well as metal fabrication and direct-to-part applications.

This partnership is the latest gain in Airtech’s continued effort to drive innovation, development and testing in the AM market.

Related Content

-

Flyber launches U.K. composites manufacturing site for advanced mobility applications

The startup’s design automation and composite material layup and curing technologies target lightweighting for aerospace, UAVs, eVTOL and high-performance mobility platforms.

-

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

-

AES explores robot vs. gantry for large-format additive manufacturing

Additive Engineering Solutions, specialist at 3D printing very large parts and tools on gantry machines, now also uses a robot for large-format AM. Here is how the robot compares.