Airtech expands large-scale additive manufacturing operations

This is Airtech’s second large-scale 3D printing machine installation, which designs, tools and builds with reduce touch labor, leadtime and improved quality.

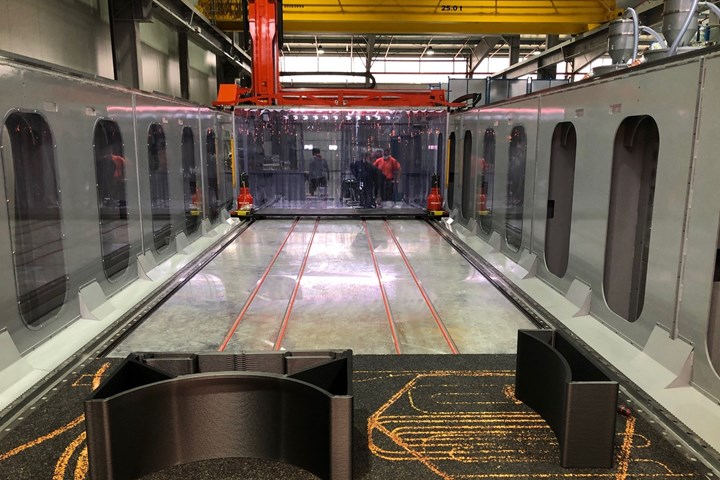

Large-scale 3D printing machine. Photo Credit: Airtech International

Airtech Advanced Materials Group (Huntington Beach, Calif., U.S.) announced on Nov. 16 the company’s installation of its second state-of-the-art machinery for large-scale 3D printing, now operable in its Europe facility in Luxembourg, as well as new thermoplastic resins for use in this machinery.

According to the company, this is the second “Center of Innovation” to develop Tooling of Tomorrow (ToT) — the first being opened by Airtech in Tennessee in 2019 — and reportedly has the same capabilities to accommodate what Airtech claims is one of the largest machinery on the market at 12 meters x 3 meters (40 feet x 10 feet), with integrated machining capabilities.

The machinery also includes a Print-Tech full-service tool manufacturing solution, which enables Airtech to take tooling from conception to the shop floor faster than conventional methods. Print-Tech’s Additive manufacturing is said to deposit only the material required, resulting in less touch labor and shorter lead times; large-scale tooling in the form of trim fixtures, holding fixtures and layup molds can be designed, tooled and built faster without compromising quality, the company adds.

Airtech has also developed a new series of innovative polymer composite resins. Dahltram resins are for use in large-scale 3D printing that has addressed the need for lower coefficient of thermal expansion (CTE) and a more robust service life when used at low or high temperatures, including use in an autoclave.

These thermoplastic composite resins — Airtech has both room-temperature and high-temperature material offerings — are designed for use in any pellet-fed FDM printing system.

Related Content

-

Hitachi Rail chooses Roboze printers, materials including carbon fiber/PEEK for railway spare parts

The Roboze ARGO 500 will be used at Hitachi Rail factories in Naples, Italy and Maryland, U.S. to reduce cost and delivery times for prototypes and spare parts.

-

Eaton developing carbon-reinforced PEKK to replace aluminum in aircraft air ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

-

Al Seer Marine, Abu Dhabi Maritime unveil world’s largest 3D-printed boat

Holding the new Guinness World Record at 11.98 meters, the 3D-printed composite water taxi used a CEAD Flexbot to print two hulls in less than 12 days.