Additional funding launches UMaine Forest Bioproducts Technology Maturation Program

Twenty-two million in funding by the NDAA accelerates Maine’s R&D support of natural polymers and other wood fiber bio-products for startups and established companies.

Senior scientist Seongkyung Park showcases a fiber thermoforming machine and how it can be used to make sustainable dinnerware at UMaine’s Process Development Center in July 2024. Source | University of Maine (UMaine)

Following by Gov. Janet Mills and Maine’s Congressional delegation that will receive an additional $22 million for the state’s forest-based biomaterial production and manufacturing, the University of Maine (UMaine) is advancing plans to launch its Forest Bioproducts Technology Maturation Program, a critical component of the Tech Hub.

The Tech Hub’s goal is to accelerate R&D of natural polymers and other wood fiber bio-products that can sequester carbon and replace plastics and toxic chemicals, while bolstering “Made in America” supply chain goals. Launched in 2023, the Tech Hub is led by the Maine Technology Institute and the Mills Administration, and supported by more than 70 partners, including Sappi, IDEXX, Thornton Tomasetti, FOR/Maine, the Maine Forest Products Council, the Manufacturers Association of Maine and the Maine Venture Fund.

As a primary Tech Hub partner, UMaine will provide innovation expertise, bio-products equipment and infrastructure, and intellectual property to build talent pipelines and help private sector companies rapidly accelerate product commercialization and operational growth.

“Maine’s Forest Bioproducts Advanced Manufacturing Tech Hub represents the future of sustainable innovation, building on two centuries of forest industry leadership and 160 years of University of Maine excellence in research, development and education along with world-class facilities,” says Joan Ferrini-Mundy, president of UMaine and its regional campus, the University of Maine at Machias, as well as vice chancellor for research and innovation for the University of Maine System. “This investment will transform ideas into real-world solutions, powered by the expertise of our talented faculty, staff and students.’

UMaine’s Forest Bioproducts Technology Maturation Program, funded at $10.5 million, will support startups and established companies in the forest bio-products space.

“The technology maturation program will provide companies with the talent, expertise and access to equipment to demonstrate new technologies and manufacturing processes at commercial scale, unlocking the potential for forest biomaterials to reach new high-value markets such as plastics and fuels replacements, textiles, building materials, biomedical applications and packaging, and create new economic development opportunities in Maine and beyond,” explains Renee Kelly, associate VP for strategic partnerships, innovation, resources and engagement.

From tailored work plans that include specific technical and business development milestones, to access to a robust network of companies and research institutions and facilities, companies that participate in the Technology Maturation Program will receive wraparound support from UMaine. In addition to facilitating technology development for individual companies, UMaine will work with companies with similar technical barriers to help reach new markets. The opportunity to work directly with experts at UMaine facilities, including the Advanced Manufacturing Center (AMC), Advanced Structures and Composites Center (ASCC) and Process Development Center (PDC), will enable companies to test and validate new bio-products and processes, focusing on scaling production and meeting safety standards. Finally, students — including undergraduate-, graduate- and doctoral-level innovation fellows — will be embedded with participating companies to support their growth.

“UMaine’s near-commercial scale Process Development Center has a decades-long history of advancing bio-based technologies,” says Colleen Walker, director of the PDC. “Our team is excited to expand our work with emerging companies and offer access to our expertise and facilities to propel the development of forest-based bio-products through the Forest Bioproducts Technology Maturation Program.”

Tanbark Molded Fiber Products is one such company that will be part of the Tech Hub network, working to accelerate novel forest biomaterials applications in collaboration with UMaine.

Maine is one of just six Tech Hubs selected to receive an award under new funding for the Tech Hubs Program included in the Fiscal Year 2025 National Defense Authorization Act (NDAA).

Related Content

Airbus works to improve the life cycle of composites in future aircraft

This companion article to CW's September 2024 Airbus Illescas plant tour discusses recycling, LCA, biocomposites, Fast Track technologies, qualification and more.

Read MoreBiomaterials make strides toward composites sustainability

A compilation of trends in development or application of natural fibers, bio-based resins and more showcases industry players, educational institutes and global projects.

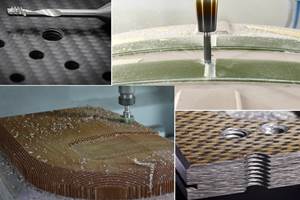

Read MoreOptimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

Read MoreBcomp ampliTex makes appearance in Cupra EV Cup Bucket seats

The entire Cupra Born VZ line-up features all-natural fiber front seats that highlight functionality, aesthetics and reduced CO2 emissions.

Read MoreRead Next

DITF, RBX Créations develops hemp-based pulp for filament-spun cellulose fibers

Partners present a complete process chain for the development of hemp-based fibers, yarns and fabrics using energy- and resource-saving processes.

Read MoreTechnikum Laubholz opens pilot plant for wood-based carbon fibers

First production phase of WDBSD CF offers sustainable alternative for high-performance composites.

Read MoreConstruction begins for UMaine sustainability research facility

The Green Engineering and Materials (GEM) building will serve as space for an additive, hybrid manufacturing test bed, future workforce training, and bio-based materials and sustainable technologies development.

Read More