Welcome to ÂÌñÏ×ÆÞ magazine

CW editor-in-chief introduces the inaugural issue (published online and in print) of ÂÌñÏ×ÆÞ magazine, the new, combined publication that, beginning Jan. 1, 2015, replaces its predecessors, High-Performance Composites and Composites Technology.

As I reported here late last year, we made the decision to consolidate sister publications High-Performance Composites (HPC) and Composites Technology (CT) into one monthly publication, called ÂÌñÏ×ÆÞ (CW). You’re viewing my first editor's column from Volume 1, Number 1 — sure to be a collector’s item.

Although the name is new and we have updated the print version's layout and design, you will find inside that much of the editorial content you have known as an HPC or CT subscriber lives on in CW. This includes regular features — Inside Manufacturing, Focus on Design and Work in Progress — and familiar columns.

However, there are two big differences in CW, and both are good. First, you will receive CW every month, instead of bi-monthly as was the case with CT and HPC. Second, you will find inside editorial content that spans the full breadth of the composites manufacturing universe, ranging, this month, from an assessment of composites use in aeroengines to a tour of ATK Aerospace Structures to the use of infusion in large marine structures to the application of carbon fiber in concrete pumping arms used in the construction industry (to read any or all, click on the article title(s) under "Editor's Picks").

In CW, we will endeavor to bring you a diverse mix of stories that focus on the design, development and manufacture of composite structures sold into a wide variety of end-markets. You’ll find stories from the aerospace, automotive, industrial, energy, building and construction, marine and consumer markets. You’ll find articles about applications of carbon fiber, glass fiber, thermosets and thermoplastics in RTM, infusion, autoclave-cure, out-of-autoclave cure, filament winding, AFP, pultrusion and other manufacturing processes and process hybrids. You will find columnists offering their thoughts on the latest in testing, design, markets and opportunities.

Finally, if you were a regular reader of HPC, you will discover in CW that one of our best-read and most revered columnists is handing his pen to the next generation. Don Adams, who has written Testing Tech since 2005, is yielding to his son, Dan Adams, who debuts this month as the anchor author of CW Design & Testing. I think you will find Dan is as knowledgeable and capable as his father, and we look forward to many more years of Testing Tech advice, guidance and education. See Don’s farewell message at right.

As always, no matter the name on the cover, we remain committed to serving your composites manufacturing information needs, whether it’s in print, online or in person. We can do that only if we hear from you — when you think we’ve done well and when you feel we’ve stumbled. Give us a call, send us a note or track us down at a trade show and let us know how we’re doing — and enjoy the new CW.

Related Content

A return to JEC World

CW editor-in-chief Scott Francis reflects on the ways in which the composites industry has changed and also stayed the same based on observations from this year’s JEC World.

Read MoreComposites and the call to space

CW editor-in-chief Scott Francis discusses the role of composites in recent and upcoming space missions.

Read MoreA return to the Space Symposium: Charting the next frontier

Since 2019 the space sector has been on a rapid upward trajectory. This year’s Space Symposium delivered that same optimism, celebrating the community’s continued proliferation, even as political and financial uncertainty raise new questions.

Read MoreParis Air Show highlights advanced materials, industry momentum

This year’s international air show offered a glimpse of the rapidly expanding future for composites in aerospace.

Read MoreRead Next

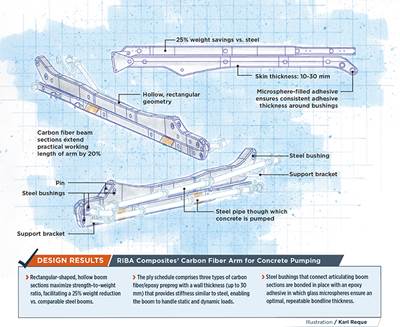

Articulated composite booms extend reach of concrete-pumping arms

A 25% weight reduction vs. legacy steel yields economics that justify upfront cost of carbon fiber.

Read MoreDark knights: Sleek trimarans surveil the seas

Epoxy-infused patrol boats outperform less nimble and more costly conventional naval craft.

Read MoreComposites in commercial aircraft engines, 2014-2023

The drive to boost aircraft operating efficiency continues to fuel adoption of polymer matrix composites in jet engines.

Read More