RTP Niches Into Low-Pressure Applications

Wellstream (a Halliburton business unit) supplies lightweight reinforced thermoplastic pipe, or RTP, which is designed for applications intermediate between those that can use low-pressure, unreinforced thermoplastic pipe or hose, and those that require high-pressure unbonded flexible pipe. Used mainly in onsh

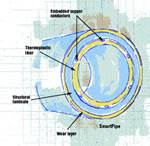

В В В В Wellstream (a Halliburton business unit) supplies lightweight reinforced thermoplastic pipe, or RTP, which is designed for applications intermediate between those that can use low-pressure, unreinforced thermoplastic pipe or hose, and those that require high-pressure unbonded flexible pipe. Used mainly in onshore flow line applications where the life cycle cost is less than steel pipe, RTP is available in sizes ranging from 3 inches/75 mm up to 10 inches/260 mm (ID). RTP features a polyethylene liner, a helically wrapped aramid fiber armor layer and an exterior ultraviolet-resistant thermoplastic barrier, and it offers service pressure as high as to 2,200 psi/150 bar.

В В В В Offshore applications likely will be shallow water installations where high collapse resistance is not needed. Here, RTP is more cost effective than steel pipe on a life-cycle or installed cost basis. Furthermore, RTPвҖҷs manufacturing process is straightforward and, therefore, offers the potential for near- or even onsite production with a modular manufacturing system. A joint industry project group вҖ” supported by BP, Coflexip Stena Offshore, Petrobras, Halliburton Subsea and Pipelife, among others вҖ” is currently developing guidelines for qualification and system design and has studied damage tolerance and repair issues. A draft ISO standard for RTP is in preparation (see Sidebar).

Related Content

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

MFFD longitudinal seams welded, world's largest CFRTP fuselage successfully completed

Fraunhofer IFAM and partners have completed left and right welds connecting the upper and lower fuselage halves and sent the 8×4-meter full-scale section to ZAL for integration with a cabin crown module and testing.

-

From the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.