On the road with ÂÌñÏ×ÆÞ

CW Senior Editor Scott Francis offers a recap of recent composites industries events including CAMX 2019 and SPE ACCE 2019.

Attendees enjoy a demonstration at CAMX 2019. CW photo | Heather Francis

September and October have been a couple of travel-filled months for the CW team. The largest composites industry event, CAMX, was held in late September and we also attended the SPE ACCE automotive composites conference as well as some facility tours and site visits (which will be featured soon in upcoming issues of ÂÌñÏ×ÆÞ magazine). In the meantime, here are a few trade show highlights including CW Senior Editor Scott Francis’ video recap from CAMX.

In early September CW attended The Society of Plastics Engineers’ (SPE, Bethel, Conn., U.S.) annual Automotive Composites Conference & Exhibition (ACCE) in Novi, Michigan, Sept. 4-6. The theme of the conference was “Composites — Forming the Future of Transportation Worldwide,” and offered a broad technology overview of evolving automotive composites industry. Much of the programming reflected a growing interest from transportation OEMs in the role composites technologies can play in next-generation mobility. If you missed the conference, here are a couple of reports that give an overview:

- “Automotive composites draw international crowd to Detroit”

- “Can the automotive industry turn to face the change?”

A couple of weeks later CAMX 2019, the largest composites and advanced materials expo in North America, took place Sept. 23-26 in Anaheim, Calififornia. The show gathered around 8,000 attendees and featured more than 520 exhibitors and was packed with technical presentations and networking opportunities.

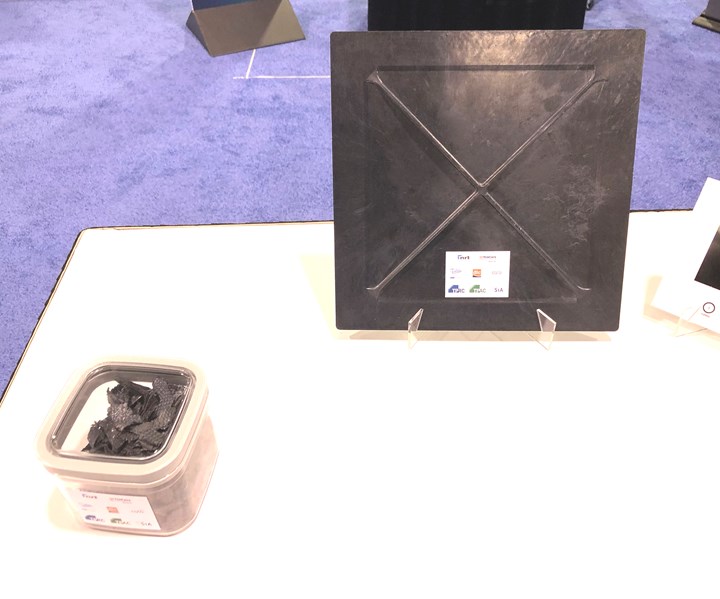

The potential for thermoplastics to enable high-volume production continues to be a big topic of discussion at the show. One example (and CAMX award finalist), is a demonstrator access panel for the Bell V-280 Valor tilt-rotor aircraft developed by the TPAC (Enschede, Netherlands) using its TPC-Cycle process, a project aimed at the re-use of production scrap from thermoplastic composites processing for aerospace and high-volume applications.

Learn more about TPAC’s demonstrator access panel in the article “The state of recycled carbon fiber” and about the TPC-Cycle process in the article “Recycled thermoplastic composites for production.”

Demonstrator access panel for rotorcraft developed using TPAC’s TPC-Cycle process. CW photo | Scott Francis

Mallinda (Denver, Colo., U.S.), a new exbitor at CAMX, showcased a new class of polymeric materials it calls Vitrimer Matrix Composites that provide the mechanical performance of traditional thermosets along with processability and recyclability similar to that of thermoplastics.

This year’s show featured an additive manufacturing workshop for composites that delved into the scope of fiber-reinforced additive manufacturing, from the use of chopped carbon fiber in large-format systems used to build molds and tools, to the use of continuous fiber reinforcement to build discrete high-performance parts and structures. Featured presentations included speakers from Ingersoll Machine Tools (Rockford, Ill., U.S.), Fortify (Boston, Mass., U.S.), CEAD Group (Delft, Zuid-Holland), Orbital Composites (San Jose, Calif., U.S.), Arevo (Milpitas, Calif., U.S.) and Markforged (Watertown, Mass., U.S.).

Orbital Composites’ composite additive manufacturing platform CW photo | Scott Francis

Orbital Composites, a new exhibitor at CAMX this year, unveiled a new product it calls Orb-S to address the needs of Industry 4.0 factories. Orbital’s manufacturing platform is designed to aid manufacturers in their transition into the Industry 4.0 and additive manufacturing revolutions. (Learn more here.)

Airtech (Huntington Beach, Calif., U.S.) announced at the show its acquisition of a Thermwood (Dale, Ind., U.S.) LSAM machine and had a large 3D printed mold on display. The LSAM relies on thermoplastic extrusion, a core competancy of Airtech, and the company says it can take tooling from conception to the shop floor significantly faster than using conventional methods. (Learn more here.)

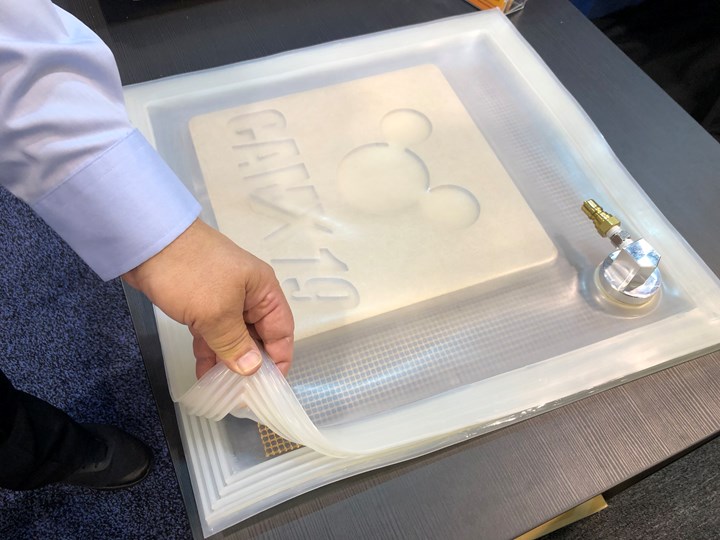

Smartech showcases Steinbach’s reusable vacuum bagging materials aimed at making vacuum forming and infusion processes easier and more cost-efficient. Products include vacuum sheets, double-sided vacuum bags and its Press | Lock Seal, which eliminates the need for tacking tape. CW photo | Scott Francis

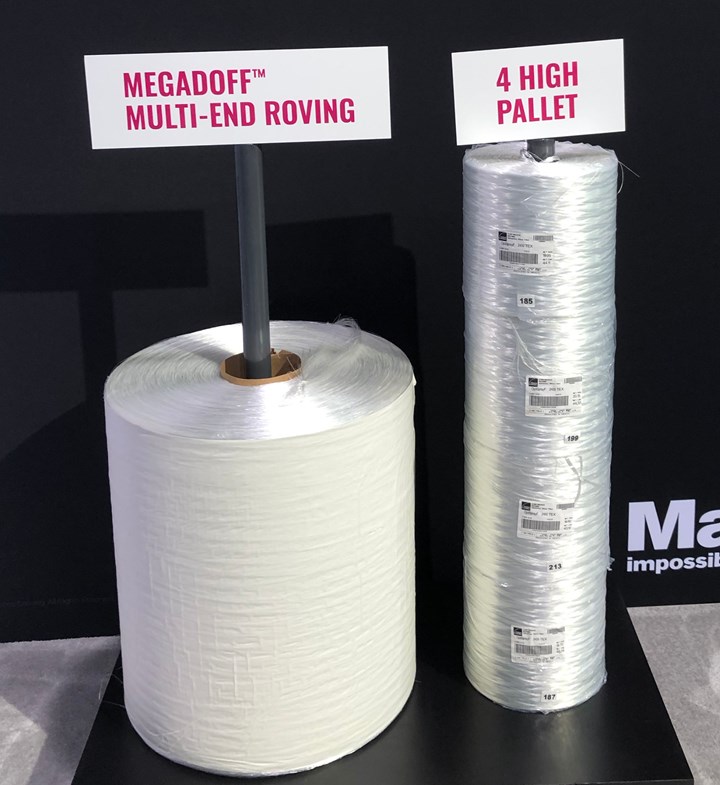

Efficiencies for increasing productivity were also on display. Examples include Smartech’s (Charlotte, N.C., U.S.) Press | Lock Seal for making vacuum forming and infusion processes easier and Owens Corning’s (Toledo, Ohio, U.S.) Megadoff multi-end roving designed to increase the continuous flow of robotic and automated manufacturing lines.

Owens Corning’s MEGADOFF increases the amount of glass from 40 pounds in a typical doff to 1,939 pounds. Increased doff weight eliminates doff-to-doff splices and improves the continuous flow of robotic and automated manufacturing lines. Zero doff transition also improves part quality and increases manufacturing throughput. CW photo | Scott Francis

For more of the happenings at CAMX, you can also check out copies of the ShowDaily:

And those are just a few quick highlights; stay tuned to CW for more insights from CAMX, site tours and much more.

Related Content

Siemens software chosen for JetZero BWB aircraft concept, launches Xcelerator updates

Aviation startup will use the Xcelerator platform to achieve its aircraft vision. Other Siemens collaborations deliver software additions to deliver, democratize industrial AI for small companies, startups.

Read MoreHow AI is improving composites operations and factory sustainability

Workforce pain points and various logistical challenges are putting operations resilience and flexibility to the test, but Industry 4.0 advancements could be the key to composites manufacturers’ transformation.

Read MoreIMDEA introduces digital twin for real-time analysis of composite materials production

Newly designed digital twin by IMDEA and Technical University of Madrid researchers enables manufacturers to see inside composite materials as they are being produced, facilitating early detection of faults.

Read MorePlant tour: Hexagon Purus, Kassel, Germany

Fully automated, Industry 4.0 line for hydrogen pressure vessels advances efficiency and versatility in small footprint for next-gen, sustainable composites production.

Read MoreRead Next

Ceramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More