Molding in fasteners to CFRP parts

Placed into the mold prior to RTM, compression or injection molding/overmolding, this specially-shaped fastener enables composites to be fastened with standard methods used for metal parts.

The goal was a fastener strong enough to fasten a composite part, but also be cost-competitive and amenable to high-volume production. “Attachment to metal floors can be easily industrialized using fully robotic processes,” says Bernard. “So the idea for IMTEC HR was an industrialized solution for composites with no manual operations.” IMTEC HR fasteners can be placed into the mold for a composite floor structure and integrated during the molding process. Bernard cites IMTEC HR as compatible with thermoset and thermoplastic molding processes, including resin transfer molding (RTM), compression molding and injection molding/overmolding.

For injection molding, the fastener is robotically placed first onto a pin fixed on the mold. The pin locates the fastener and protects the threads inside of it from being coated with resin. Next, the composite material is robotically placed into the mold. The mold is closed, the plastic injected and the part demolded with fastener integrated.

For compression molding, the process is essentially the same except the pin is a plastic screw-off “cap” and also serves to push the material aside for inserting the fastener into the composite, thereby eliminating the need for hole drilling. This not only saves time, it avoids cutting the fibers. The pin cap again protects interior threads during molding and is removed after the part is demolded.

“There are no extra operations once the floor is produced,” notes Bernard. “We believe this technology helps to make composite floors or any other structural parts with an affordable production cost. It replicates the used of blind rivets with metal floors because the fastener is already there in the molded composite part. You now attach the seat with standard methods. This equals the playing field because parts can be attached to a composite floor the same as to a metal floor.”

SOURCE: Böllhoff

To resist galvanic corrosion, IMTEC HR is available in zinc-plated steel and in stainless steel, the latter used mainly for carbon fiber reinforced plastic (CFRP). Different fastener versions are also available, including bolts (studs), nuts and spacers. “We can also change the size of the holes and dimensions of the fastener to meet specific requirements,” says Bernard.

Special shape for energy absorption

I asked Bernard about the shape of these fasteners, explaining they looked similar to others I had seen, including Big Head and Spida Fixings. He said the shape is reminiscent but different, developed to allow the gradual release of energy during crash conditions. “It is strong enough to provide a high mechanical performance but can absorb energy in crash test conditions to avoid catastrophic brittle failure,” he explains. “It enables elastic then plastic deformation without breaking. Without this behavior, the composite floor at the attachment would deform and break or the metallic fastener would break. This was one issue with adapting fasteners for composite structures.”

|

|

Big Head (left) and Spida Fixings (right) fasteners for composites.

SOURCE: and .

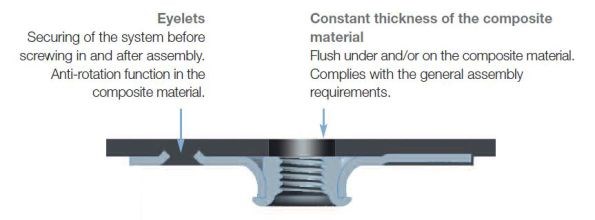

Another aspect of the shape is the petals. “These are designed to embed in the composite material during molding,” says Bernard. “You must design this fastener to embed in the part and not be left in the mold.” He also notes that the fastener flange is behind the composite part and does not reduce the part section thickness. “This is important to achieve an embedded fastener while maintaining the part section, which gives structural properties.”

Böllhoff’s IMTEC HR fastener developed for molding process embeds into the composite part without reducing section thickness. SOURCE: Böllhoff.

A special version of IMTEC® HR has been developed with Cetim which is compatible with the QSP production line. Cetim is the French research organization that has developed the Quilted Stratum Process (QSP) for highly automated production of composite parts.

According to an article published by Cetim, the patent pending IMTEC HR fastener developed for QSP shows a 30-75% increase in pull-through performance and 60-75% improvement in lap-shear performance compared to conventional fasteners.

Related Content

Co-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreJEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

Read MoreDevelopment of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreRead Next

Automated Preforming, Part 3: Quilted Stratum Process

CW’s tour of Cetim and the QSP line which preforms multi-thickness thermoplastic materials in 40-90 seconds for composite parts with cycle times of 1-2 minutes.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More