Carbon fiber elevator rope rides to the rescue high in the sky

Steel rope was once the material of choice for elevator function, but as buildings exceed 500m in height, it's just too heavy. Elevator manufacturer KONE is offering pultruded carbon fiber rope, called UltraRope, for elevators in the world's tallest buildings.

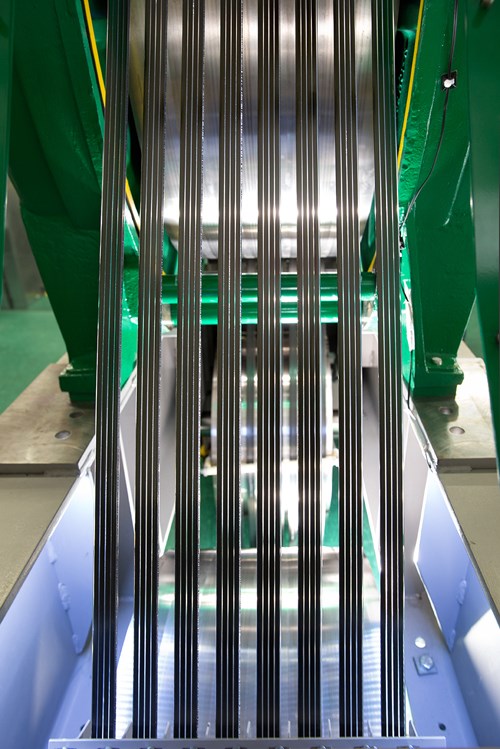

Pultruded carbon fiber KONE UltraRope installed in an elevator shaft.

Elevators are one of those everyday machines that are uncommonly easy to take for granted, but whose function depends on a myriad of material and devices that go largely unseen — and must function flawlessly.

One of those unseen devices is the system of steel rope that attach to and ride with an elevator. They have worked dependably for many years, but have one flaw that makes them unusable in the super-tall buildings that dominate urban landscapes: They are too heavy.

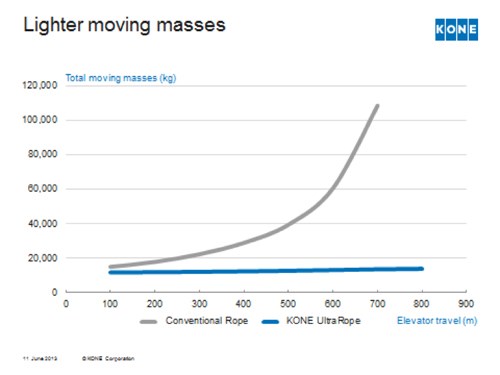

Indeed, says Simon Barrette, communications manager at elevator manufacturer KONE (Espoo, Finland), current steel rope technology has reached its height limit: elevator travel distances of more than 500m are not feasible as the weight of the ropes themselves becomes so large that more ropes are needed to carry the ropes themselves. In short: Rope weight increases exponentially with building height.

A few years ago, KONE's customers started asking if there was a way to eliminate steel ropes in elevator design. This, says Barrette, "began our research into finding ways to reduce the weight of the ropes and we started looking at alternative materials. We benchmarked solutions from other industries and came across carbon fiber technology, which has already been used to reduce weight in industries such as aviation, automotive and the machine industry."

In 2013, KONE launched the KONE UltraRope, a belt-like rope fabricated via pultrusion with carbon fiber, with a polyurethane coating. Barrette says KONE UltraRope was patented in 2008 and research of the application properties including thorough testing was conducted for seven years. According to the KONE patent for UltraRope, the rope is wider than it is thick, features a series of V-shaped longitudinal grooves, and can be pultruded with epoxy, polyester, phenoic or vinyl ester resins. The rope was tested at KONE's Hyvinkää reliability lab and testing towers, as well as at the Tytyri high-rise testing facility. Focus areas have been lifetime, environmental effects, temperature behaviors and friction properties in applicable conditions.

Steel rope, as elevator travel increases, exponentially increases the total moving mass of the elevator. KONE UltraRope, made with pultruded carbon fiber, dramatically reduces moving mass.

The result? KONE UltraRope will reduce the total cost of ownership thanks to significant reduction of energy consumption, reduction of downtime caused by building sway and the longer lifetime (2X) of ropes themselves, compared to steel. For an elevator with a travel height of 500m, energy savings would be approximately 30%. For an elevator with a travel height of 800m, energy savings would be as much as 45%.

Carbon fiber also offers an ancillary benefit as well, says Barrette. "In strong winds buildings start to sway, which also causes ropes to sway," he says. "At certain elevator positions rope resonance cannot be totally eliminated and for safety reasons elevator speed needs to be reduced or the elevators need to be completely stopped. KONE UltraRope resonates at a higher frequency than steel and most other building materials, meaning it is less likely to start resonating in high winds and this problem is minimized. Typically, building sway for very tall buildings is measured in tens of centimeters; in extreme cases, the sway can be more."

The first elevator hoisted with KONE UltraRope was installed in one of Marina Bay Sands resort’s elevators in Singapore in September 2013. The Kingdom Tower Jeddah (Jeddah, Saudi Arabia), the world’s future tallest building (1 km high) once completed at the end of 2018, will feature KONE UltraRope technology and the fastest and longest DoubleDeck elevators in the world.

Kingdom Tower Jeddah, in Jeddah, Saudi Arabia, when completed in 2019, will be the tallest building in the world at 1 km (1,000m). For comparison, the Freedom Tower in New York City is less than half that height at 417m.

Related Content

Flyber launches U.K. composites manufacturing site for advanced mobility applications

The startup’s design automation and composite material layup and curing technologies target lightweighting for aerospace, UAVs, eVTOL and high-performance mobility platforms.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreComposite Integration presents webinar on liquid resin infusion

On July 30, 2025, company experts will discuss the role of LRI in delivering scalable, OOA composite production for the aerospace sector.

Read MoreRead Next

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More