For the Corvette, a smooth ride depends on composites

On a vehicle already famous for having a long history of composites use, finding a new part on which to apply the material is a challenge, but PolyOne’s Advanced Composites Glasforms unit managed to do just that.

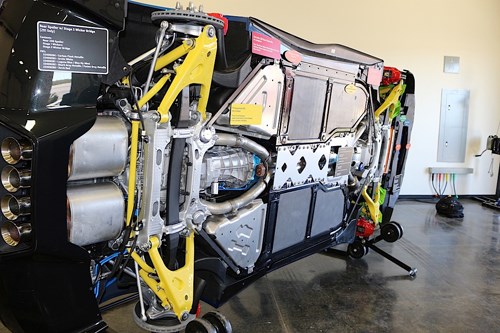

Underbody braces for the Corvette C7, made via pultrusion and overwrapped carbon fiber fabric.

On a vehicle already famous for having a long history of composites use, finding a new part on which to apply the material is a challenge, but PolyOne’s Advanced Composites Glasforms unit managed to do just that with the underbody braces designed for the C7 generation Corvette, manufactured by General Motors (GM).

Ben Hochman, director of marketing at Glasforms, says he and his team had been meeting with GM engineers and discussing material and technical challenges on the Corvette. The topic of underbody braces came up. GM wanted to get away from the steel braces traditionally used and had developed an aluminum alternative that, unfortunately, was somewhat lacking in flexural stiffness. The result, says Hochman, was a less-than-optimal driving experience.

GM then turned to composites, but the challenge was developing the mechanical properties in all directions that the company required. And that’s where Glasforms stepped in.

There are four underbody braces on the Corvette — one associated with each wheel. Each brace is about 2 ft long, 1.25 inches wide, 0.375 inch thick, and notched at each end to accommodate metallic fasteners. The braces are designed to reduce chassis sway and confer greater stability in vehicle handling, giving a tighter “feel” to the driving experience. Basically, as underbody brace stiffness increases, so does handling stiffness. The “feel” of the Corvette has been highly developed by GM, and is expected by drivers. A composite underbody brace must, therefore, allow the Corvette to continue to meet that expectation.

Underside of Corvette. The braces are the black, narrow, diagonally oriented rods running from the outside edge of the vehicle toward the yellow wheel suspension system.

Hochman says Glasforms settled on an underbody brace design that would use a carbon fiber/epoxy composite manufactured via pultrusion. Pultrusion offers a constant cross-section, high stiffness and good longitudinal fiber alignment. What a pultruded part lacks, however, is good transverse strength. To manage that, says Hochman, “We developed three design scenarios for the brace, mixing and matching torsion and flexural stiffness.”

- A unidirectional, hybrid carbon and glass fiber profile

- A unidirectional carbon fiber profile

- A profile made with a unidirectional carbon fiber and a transverse engineered fabric, which had the advantage of minimizing potential cracks from propagating.

Testing at Wichita State University showed that the first option was an estimated 33% lighter than the aluminum part, with a 36% increase in flexural stiffness. The second option was estimated to be 41% lighter than the aluminum part, with a 100% increase in flexural stiffness, but a large reduction in torsional rigidity. The third profile was also 41% lighter than aluminum, with a 50% increase in flexural stiffness, and maintained torsional rigidity slightly better than that of aluminum.

GM engineers chose this third option because it met all of the technical requirements and had the best combination of properties.

The resulting brace assemblies, ultimately 17% lighter than their aluminum competitors, were delivered to GM for vehicle shake and road testing. They were validated and now are an upgrade option on the C7 Corvette.

Glasforms does all carbon fiber underbody brace manufacturing and has, says Hochman, “seen an increase in interest since the product’s release. The discerning buyer is very intrigued by the performance properties of these braces.”

Looking ahead, Hochman believes the braces have application on other vehicle platforms. He thinks Glasforms’ knowledge on composite design and manufacture will allow the company to adapt easily to other structural applications in automotive composites.

Related Content

From the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreInduction heating system enables OOA composites processing

JEC World 2025: Roctool focuses attendees’ attention on the light induction tooling (LIT) system targeting efficiency, sustainability and performance.

Read MoreCOMPINNOV TP2 project promotes use of thermoplastics in aerospace

Completed in 2023, COMPINNOV TP2 explored thermoplastic composites, enhancing the understanding between prepregs and production methods to foster the potential for French aerospace innovation.

Read MoreComposite Integration presents webinar on liquid resin infusion

On July 30, 2025, company experts will discuss the role of LRI in delivering scalable, OOA composite production for the aerospace sector.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAssembling the Multifunctional Fuselage Demonstrator: The final welds

Building the all-thermoplastic composite fuselage demonstrator comes to an end with continuous ultrasonic welding of the RH longitudinal fuselage joint and resistance welding for coupling of the fuselage frames across the upper and lower halves.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More