Designing with composites: Optimizing for performance and manufacturing

David Leigh Hudson, the director of product and market strategy for the Fibersim product portfolio at Siemens PLM Software (Waltham, MA, US), the need in the field of composite part design for a serious commitment to what he terms "concurrent engineering" processes.

The choice to design with composites is often driven by market demand and cost. The promise of mass reductions, performance improvements and material and assembly cost reductions is enticing, but realizing a design with fiber-reinforced plastic (FRP) remains challenging. As FRP become the material of choice, based on design potential, traditional methods of analysis, design and manufacturing will not suffice. Based purely on the nature of the material itself, a composite design must be optimized not only for finished part performance but for manufacturability as well. Specifically, analysis and design must be performed in the context of the manufacturing process. Therefore, composite design requires a serious commitment to what I’ll call concurrent engineering processes.

FRP parts are “inseparable assemblies” made up of tens to hundreds of plies that vary in number, and therefore thickness, across the desired part geometry. A combination of the part geometry, the material form and the manufacturing process affects the fiber orientations within the part; therefore, understanding all three characteristics is critical during the design phase. Fibers that deviate from the analyst’s defined orientations will affect structural performance due to a significant impact on modulus and strength. In addition, in-plane or out-of-plane deformations that occur during production will result in increased manufacturing cost and effort to resolve issues downstream.

Preliminary analysis of composite parts is often performed based on idealized geometry and fiber orientations that meet loading conditions. However, without the understanding of fiber deviation, material knockdown factors are used to reduce the material’s mechanical properties. The result is an overbuilt composite part, which neither achieves the structural performance nor the desired mass reductions. Virtual visibility into the deviation and deformation of the material during the manufacturing process can minimize the risk of overdesigning parts. Often referred to as “simulation of manufacturing producibility,” this software-based capability is where the true fiber orientations can be known and then can be exchanged with those who do the analysis, as illustrated in Fig. 1, at left.

Taking a closer look, the detailed design process is started by importing the material lay-up from the analyzed finite element model and applying it to the CAD part. Next, the designer and manufacturing engineer, together, elect the best lay-up process and simulate it in the CAD environment, making the detailed part the basis for understanding the resulting material fiber orientations (Fig. 2). The resulting material properties and true fiber orientations are then passed back to the analyst’s pre-/post-solution, ensuring that local fiber orientations are known; thus, the analyst no longer is relying on theoretical orientations. The result is a part identified by correlating non-linear analysis with real part behavior, and can be designed within tight safety margins.

Delivering an optimized composite part requires that the fiber orientations of the production part fall within tolerance of an analyst’s desired part, which requires consistent manufacturing. Today, the majority of composite parts are still produced with manual lay-up processes, which innately introduce the risk of inconsistency. Although consistency increases when automated manufacturing processes are employed, additional constraints are introduced, which can affect fiber orientations, thus impacting designed performance. In the case of automated tape laying and fiber placement methods, for example, intended fiber orientation can be constrained by material radius-of-curvature limits. To ensure consistency, then, it is always necessary to compare the as-manufactured fiber orientations with the as-designed orientations (Fig. 3), and to communicate the simulated lay-up process used in part and flat pattern development (Fig. 4). Consistency can be achieved by simulating the manufacturing process in the context of the desired fiber orientations, ensuring delivery of an optimized composite part for performance and manufacturing.

To learn more, register for Siemens PLM Software’s Webinar on Thursday, Aug. 20, 2015 |

Related Content

Optimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

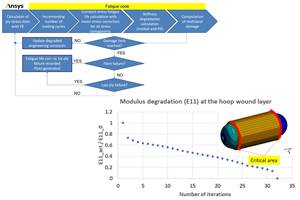

Read MoreNumerical tool with mean stress correction demonstrated for fatigue life estimation of thermoplastic composites

To aid design of fatigue-resistant structures, Econ Engineering has developed an algorithm to evaluate ply-based cyclic stiffness degradation combined with an FE failure check, validated for a CF/PAEK pressure vessel.

Read MoreActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read MoreOptimized rib-reinforced hollow composites via printed molds

Addyx topology optimization and water-soluble mandrel enables simultaneous rib and skin layup for one-shot, high-strength, lightweight structures.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreComposites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

Read More