Composites on the re-engined 737NE?

Jeff Sloan, editor-in-chief of High-Performance Composites magazine, comments on the impact of The Boeing Co.'s (Chicago, Ill.) decision to re-engine its fabled 737 single-aisle passenger jet. What remains to be seen, he says, are what composites opportunities there might be on the 737NE.

If you are a student of capitalism and the competitive marketplace it engenders, the summer of 2011 has provided one case history/soap opera that has immediate and long-term consequences for the aerospace composites community. This tale involves, not surprisingly, Airbus and Boeing, and highlights just how quickly even the biggest of companies can act to preserve their place in the market.

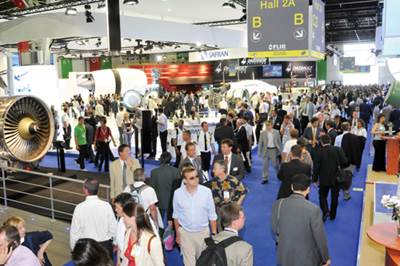

This story, brewing for several months, began in earnest the week of June 20 at the Paris Air Show, where Boeing faced a big question: Should it follow Airbus’ lead with the A320neo (a version of the current A320 re-engined for greater fuel-efficiency) and re-engine its 737, or take the bold step of replacing it with an all-new aircraft? The former would preserve the mostly aluminum construction of the current 737 design but could be accomplished within a few years. The latter offered the possible use of carbon fiber composites in many structural components, similar to the 787 program but would not enter service until the end of this decade.

In our report on the 2011 Paris Air Show (see "Editor's Picks," at top right), you’ll discover that Boeing, at that event, was still undecided. There were, at the time, compelling reasons for the company to go either way. And composites were discussed as an option on a new aircraft — one that might even feature a twin-aisle configuration.

Then, a funny thing happened: The Paris show was, for all intents and purposes, the coming out party for the A320neo, and the excitement, energy and orders (more than 350 for the A320neo at the show, and more than 1,000, total) proved that commercial airlines were happy to sign up for a more efficient version of an established plane. Perhaps the Paris experience alone convinced Boeing to re-engine the 737 and bypass a new plane.

But if that wasn’t enough, the final nudge came when American Airlines (AA), long a buyer of U.S.-made craft, placed the largest aircraft order ever, split between the Airbus A320 family and the Boeing 737 family. The order, announced on July 20, includes 130 current-generation A320s and 130 of the forthcoming A320neo. From Boeing, AA ordered 100 737NG craft and, notably, 100 re-engined 737s.

The news that AA’s order included a re-engined 737, issued somewhat unusually by Boeing at a press conference with AA and Airbus, was a revelation and appears to signal once and for all that Boeing has finally gotten off the fence. Even this news, however, was almost buried in the third paragraph of Boeing’s press release:

"In addition, American Airlines has committed to order a variant of the 737 featuring new more fuel-efficient engines, pending final airplane configuration and launch approval of the program by the Boeing board of directors. This commitment for 100 airplanes, with options for 60 more, is the first of many anticipated for this variant. The airplane would be powered by CFM International’s LEAP-X engine."

Certainly, Boeing could not risk losing any part of this massive order. Does that mean the company was rushed to a decision to develop what is now called the 737NE (new engine)? Maybe, maybe not. Although an all-new craft might have been a boon to the composites industry and its demise is disappointing, many questions have been raised recently about the ability of current composites manufacturing technology to match the production speeds demanded by a 737-type craft. Plus, a new plane, as the 787 has proved, can consume many valuable years and resources.

What remains to be seen are what composites opportunities there might be on the 737NE. The CFM LEAP-X engine integrates many composite materials, so it’s not unreasonable to think that certain components on the 737NE might be converted to composites to make the re-engined 737 as fuel-efficient as possible.

Stay tuned.

Related Content

Looking back at 2023 to look forward

As 2024 begins, we look at trending topics and our most-read stories in 2023, plus highlight new content for the new year.

Read MoreFall events chart the course for composites

A busy fall brings industry-leading events and recognition for operations setting new benchmarks for excellence.

Read MoreLooking at composites through the lens of U.S. history

When you’re a tourist with a background in writing for manufacturing it’s impossible not to notice all of the ways in which composites have resulted in significant milestones in the U.S. — historically and in the present.

Read MoreComposites and the call to space

CW editor-in-chief Scott Francis discusses the role of composites in recent and upcoming space missions.

Read MoreRead Next

2011 International Paris Air Show

At the 49th event, records are set for attendance and aircraft orders, and airframers go on record about composites-related developments.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More