Composites help bring Shanghai Disneyland’s Tomorrowland alive

Many sections of both the interior and exterior of the buildings and rides were made from fire retardant gelcoated FRP composite molded parts.

The super new and modern Shanghai Disneyland is home to some lands not found in other Disney parks, however, one staple remains: Tomorrowland. And composites had a hand to bring the futuristic Tomorrowland to life. Extensive sections of both the interior and exterior of the buildings and rides in Tomorrowland were constructed from fire retardant (FR) gelcoated FRP composite molded parts in several hundred different shaped and sized components.

Construction finishes on the gold-colored FRP parts on the main concourse of Tomorrrowland. Photo credit: Jessica Lee, E-Grow.

All of the FRP components needed for Tomorrowland were hand lay-up, manufactured by the specialist composites fabricator E-Grow, Shanghai, using a fire-approved laminate system comprising of Scott Bader's, Wollaston, Northamptonshire, UK, Crestapol 1212 ATH filled urethane acrylate resin, with the fire retardant pre-accelerated Iso-NPG polyester gelcoat Crystic 967 FR, supplied in a variety of specified custom colors.

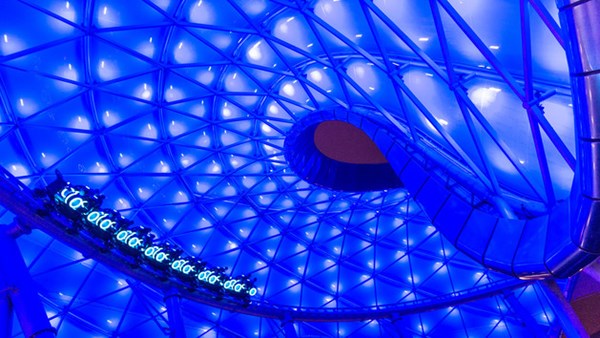

Several hundred different sized and shaped gelcoated FRP parts were produced by E-Grow for Tomorrowland. The FRP composite parts supplied included facades, passenger sections of the Tron roller coaster (which reviews say is the most thrilling ride at the park), parts of the Buzz Lightyear ride, the Lilo & Stitch Theatre, outdoor dining furniture and exterior cladding on the concourse and surrounding facilities.

To cost effectively produce all of the different sizes and shapes for the Tomorrowland project, E-Grow used a unique, patented wax mold process. Using a 3D CAM file, individual plugs are CNC milled directly from wax blocks to produce the mold plug. The wax plugs, which include surface texture and design details, are then used to cast large gypsum-based mold tools for the hand lay-up process. Once all the FRP parts are produced, the wax plug is melted down and reused.

All FRP used in the park had to meet the Chinese B1 ‘reaction to fire’ classification for fully assembled composite parts, as stipulated and tested by the Chinese National Inspection and Testing Center for Building and Engineering Materials. To ensure that the fire specification was met, E–Grow used Crestapol 1212 urethane acrylate loaded with 170phr aluminum trihydrate (ATH) as the backup resin 450 gsm CSM and 450 gsm woven rovings glass fiber reinforcements were added as needed.

‘Tomorrowland’ restaurant and outdoor dining area. Photo credit: Jessica Lee, E-Grow.

Another Disney requirement was that all gelcoat be both fire-resistant and match the paint system so that should there be any damage to the paint surface the part would maintain its appearance. To meet these requirements, E-Grow used eight custom colors of Crystic Gelcoat 967 FR fire retardant pre-accelerated, thixotropic Iso-NPG polyester airless spray gelcoat. Crystic Gelcoat 967FR was specially designed by Scott Bader for the production of GRP parts in the building and transportation industry in areas where fire resistance is a key requirement.

Scott Bader’s Asia-Pacific team in Shanghai supplied E-Grow with materials according to a planned production call off schedule for each of the build phases of the construction project. The team managed all the inventory and supply chain logistics from Scott Bader’s production plants in the UK for the Crestapol resin, and in Dubai, UAE, for the eight different colors of the high performance fire retardant Crystic gelcoat.

Who's ready to ride the Tron roller coaster?

Related Content

Pultron Composites GFRP rebar addresses facility, marina project challenges

The company’s Mateenbar GFRP rebar has led to more durable solutions for production of a new medical research center, and to improve structures regularly exposed to harsh marine conditions.

Read MoreBrainDrip scales up composite technology to meet current, future energy infrastructure needs

Next-generation composite pipe development with embedded, AI-enhanced health monitoring will modernize new and aging pipelines globally.

Read MoreComposites end markets: Infrastructure and construction (2024)

Composites are increasingly used in applications like building facades, bridges, utility poles, wastewater treatment pipes, repair solutions and more.

Read MoreSustainable Infrastructure Systems creates fiber-reinforced post-consumer plastic structural panels

Australian composites manufacturer offers a scalable building solution, already established in a pedestrian bridge application, to tackle unprocessed soft plastics waste.

Read MoreRead Next

Ceramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More