Choosing composite material testing methods

An initial step in selecting suitable test methods involves consulting the available test literature.

When first introduced to mechanical testing of composite materials, one can be confused, even overwhelmed, by the number of available test standards. One reason for this large variety of tests is the number of stiffness and strength properties that must be determined. Material properties for a unidirectional fiber-reinforced composite (Fig. 1, above) might not only be required in the fiber direction (1), but also the transverse direction (2) and possibly the out-of-plane direction (3). Similarly, shear properties might be required in the in-plane (1-2) orientation as well as two interlaminar (1-3 and 2-3) orientations. Adding to the list of properties, tension and compression strengths are usually different and are determined by performing separate tests.

Further complicating matters, there are multiple standardized tests available for determining each of these material properties. Differences between tests include the size and shape of the test specimen, the manner in which the load is applied to the specimen, and the procedure followed when performing the test. Compression and shear testing of unidirectional composites provide good examples of these differences.

For compression testing of composites in the fiber direction, commonly used standardized

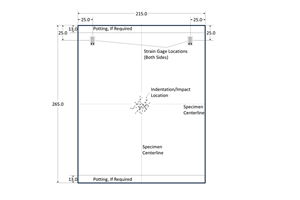

tests exist that introduce the compression load into the specimen through either shear loading of the specimen faces (ASTM D 34101), compression loading of the specimen ends (SACMA SRM2) or a combination of shear and compression loading (ASTM D 66413). When performed properly, all three load-introduction methods are capable of producing the same stiffness and strength properties. In the case of in-plane shear testing, standardized tests exhibit more fundamental differences. The most-used in-plane shear test methods are the ±45° tension shear test (ASTM D 35184) and the V-notched shear tests (ASTM D 53795 and D 70786). In the ±45° tension shear test, tensile loading of a composite laminate fabricated from ±45° layers produces the desired shear stresses in the 1-2 orientation of each layer (Fig. 2). In contrast, shear stress is produced in V-notched shear specimens through either edge loading (ASTM D 5379) or face loading (ASTM D 7078) as shown in Fig. 2. Despite big differences in specimens and loading methods, all three shear test methods can be used to generate in-plane shear modulus and shear strength of composite materials.

In addition to mechanical tests used to determine material properties of composite materials, additional testing is typically performed to obtain structural properties associated with multi- directional composite laminates. Similar to the material property tests described above, multiple standardized test methods exist for each type of structural test. However, additional complications arise when selecting a test method based on differences in the intended use for the test results.

For example, consider the variety of bearing test methods commonly used for composites testing and summarized in my . For material comparisons, the relatively simple double-shear configuration with a hardened pin and loaded in tension is commonly used. When testing to represent an intended use, however, bearing testing may feature the specific fastener, countersinking and bolt torque to be used along with a representative joint configuration and loading.

So how does one go about selecting the most suitable test method for a particular type of test? The initial step includes identifying the available standardized test methods and understanding the important differences between them. For standardized test methods published by ASTM International, a useful guide to the various composite test methods is available in ASTM D 47627. The 108 ASTM test methods summarized in the

guide are arranged into six test categories:

- Lamina/Laminate Static Properties

- Lamina/Laminate Dynamic Properties

- Laminate/Structural Response

- Sandwich Constructions

- Constituent/Precursor/Thermophysical Properties

- Environmental Conditioning/Resistance

For each test category, a table is presented listing the associated ASTM standardized test methods, along with a summary of the specimen configuration, the measured properties, a brief test description, advantages and disadvantages of the test and other comments. Although the table entries are relatively brief, they provide useful overviews and comparisons of the standardized test methods.

A significantly more detailed source of information for standardized tests is the Composite Materials Handbook8, commonly referred to as CMH-17. Volume 1 of the Handbook, titled, “Polymer Matrix Composites Guidelines for Characterization of Structural Materials,” includes detailed discussions on a variety of composite test methods. Of particular interest are Chapter 6 (“Lamina, Laminate, and Special Form Characterization”) and Chapter 7 (“Structural Element Characterization”). Although a majority of the test methods discussed in CMH-17 are ASTM standards, other commonly used test methods are reviewed, including those published by the former Suppliers of Advanced Composite Materials Assn. (SACMA). Having identified candidate standardized test methods and developed an understanding of their capabilities, the final selection of the test method most suitable for a particular situation typically is based on a variety of considerations:

- The composite material to be tested, including the type of constituents (fiber and matrix) and the material form (continuous or discontinuous fiber, unidirectional, random mat, woven, etc.)

- The material or structural properties desired — stiffness properties strength properties, or both.

- The time, equipment and expertise required to perform the test.

Perhaps the most important consideration, however, is the intended use of the test results. When intended for use in quality control or for comparative testing of candidate materials, the simplicity of the test method and its ability to identify material variations are important considerations.

However, when test results are intended for use in material databases or for structural design and analysis, the stress state produced in the test specimen and the production of the desired failure mode(s) are of primary importance. Further, test method consistency is an important consideration for all intended uses and, therefore, one must consider what methods and procedures were used in previous testing. As a result of these considerations, different standardized tests may be deemed most suitable when used for different purposes.

References

1ASTM D 3410/D 3410M-16, “Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials with Unsupported Gage Section by Shear Loading,” ASTM International (W. Conshohocken, PA, US), 2016 (first issued in 1975).

2SACMA Recommended Method SRM 1R-94, “Compressive Properties of Oriented Fiber-Resin Composites,” Suppliers of Advanced Composite Materials Assn. (SACMA, Arlington, VA, US), 1994.

3ASTM D 6641/D 6641M-16, “Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture,” ASTM International (W. Conshohocken, PA, US), 2016 (first issued in 2001).

4ASTM D 3518/D 3518M-13, “Standard Test Method for In-Plane Shear Response of Polymer Matrix Composite Materials by Tensile Test of a ±45° Laminate,” ASTM International (W. Conshohocken, PA, US), 2013 (first issued in 1994).

5ASTM D 5379/D 5379 M-12, “Standard Test Method for Shear Properties of Composite Materials by the V-Notched Beam Method,” ASTM International (W. Conshohocken, PA, US), 2012 (first issued in 1993).

6ASTM D 7078/D 7078 M-12, “Standard Test Method for Shear Properties of Composite Materials by the V-Notched Rail Shear Method,” ASTM International (W. Conshohocken, PA, US), 2012 (first issued in 2005).

7ASTM D 4762-16, “Standard Guide for Testing Polymer Matrix Composite Materials,” ASTM International (W. Conshohocken, PA, US), 2016 (first issued in 1988).

8Composite Materials Handbook (CMH-17), Volume 1: “Polymer Matrix Composites: Guidelines for Characterization of Structural Materials,” Composite Materials Handbook 17 Organization (Wichita, KS, US), Rev. G, published 2012.

Related Content

Crashworthiness testing of composites: A building block approach, Part 3

Third in a series on crashworthiness testing analyzes the upper levels of the building block approach and the importance of numerical analyses.

Read MoreUsing multidisciplinary simulation, real-time process monitoring to improve composite pressure vessels

Multi-pronged approach closes the loop between design and production of Type 3, 4 and 5 pressure vessels, enabling simulation of as-built composite tanks to improve performance and storage capacity while reducing weight and cost.

Read MorePhotothermal tomography for locating, quantifying defects in composites

Years of infrared testing development result in thermography technology that is no longer just qualitative, but can define defect size and depth, making additional UT scans obsolete.

Read MoreDamage tolerance testing of sandwich composites: The sandwich CAI test

A new ASTM-standardized test method established in 2022 assesses the compression-loaded damage tolerance of sandwich composites.

Read MoreRead Next

Scaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More