This is my 175th editorial for ÂÌñÏ×ÆÞ. I probably should have paused at the 100th or 150th milestones to look back on my work, but those came and went without me noticing. And I guess I could wait a couple of years for my 200th editorial to make a big deal of things, but this seems like as good a time as any.

The question I faced, as I began this effort, was how to assess 15 years’ worth of editorials. Do I go back and pick out what I consider notable or interesting and see how they resonate (or don’t resonate) today? Do I look for trends in my commentary, and how would I do this? And how do I do any of this without rereading every editorial I ever wrote — which, frankly, doesn’t sound that fun.

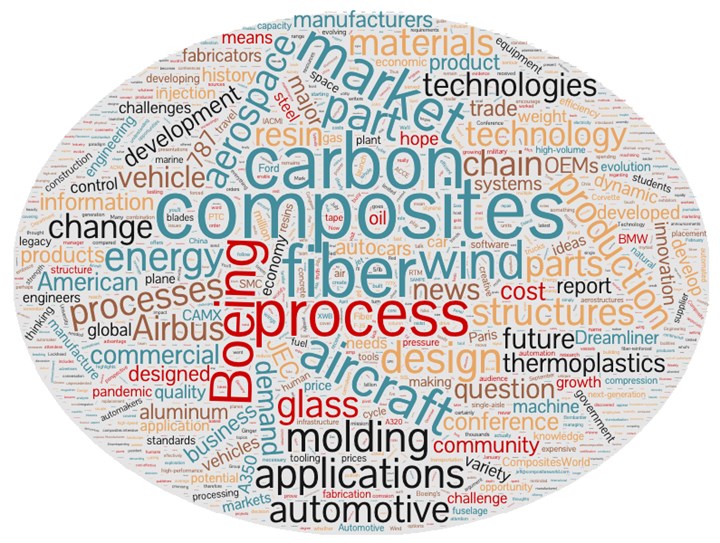

It was then that I struck upon the idea of dumping all 104,322 words I have written in 175 editorials into a word cloud, and seeing what that looked like. This, I thought, might be a good way of identifying some of the recurring terms and ideas that have received attention in my editorials over the years. The final result is below.

So, what do we make of this? A few things stand out for me. First, the most obvious things. The dominant words are those you might expect to find in a compilation of editorials about the composites industry spanning 2007-2021 — composites, fiber, carbon, glass, process, market, aerospace, automotive. Boeing, Airbus, the 787 and the A350 got — and continue to get — a lot of attention from me because of their importance to the industry. But I would also remind you that the 787 and the A350 were launched during this window of time, and those aircraft were vital to the advancement of myriad composite technologies. You’ll also notice that wind is prominent. Early in my editorial writing I often opined on the U.S. production tax credit (PTC), the now-expired federal subsidy for wind farm owners. Whenever I wrote about the PTC, I usually bemoaned the fact that the U.S. Congress had a difficult time consistently renewing it, which created uncertainty for wind turbine manufacturers. And uncertainty for any business, as you know, is frowned upon.

What else do I notice? Future, change, technologies, development, ideas and innovation speak to the dynamic (that’s in there too) nature of the composites industry, fueled in large part by the vast array of resins, fibers, fiber formats, manufacturing processes and end markets at play in the composites community. In fact, this dynamism — and the innovation it breeds — might be the one theme I have returned to most often in the last 15 years. And as I have noted before, this large selection and variability offered by the composites industry is a blessing (mostly) and a curse (occasionally).

A few other things jump out at me. The word “oil,” right in the middle, is bigger than I would have expected. There was a time when we tracked the price of oil more closely, thinking that as oil prices rose, automakers might be motivated to build lighter-weight and thus more fuel-efficient cars. I could see why I would think such a thing, but in retrospect, it doesn’t make much sense. Most car-buyers are not sensitive to fuel efficiency, which leads to little market demand for more fuel-efficient vehicles.

The word “cost” also caught my eye. I am dead certain this word was almost always used in reference to the high cost of carbon fiber and the challenge that poses to the expanded use of carbon fiber. Maybe this challenge will be met before I write another 175 editorials.

Finally, I draw your attention to “hope.” I’m glad hope got some love in the cloud. I am, generally, an optimistic and hopeful person, and it’s reassuring to see that I deployed those ideas somewhat regularly. So, I hope you enjoy this word cloud and if you have your own observations about it, I hope you will share them with me at jeff@compositesworld.com.

Related Content

Composites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

Read MoreRTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

Read MoreHonda begins production of 2025 CR-V e:FCEV with Type 4 hydrogen tanks in U.S.

Model includes new technologies produced at Performance Manufacturing Center (PMC) in Marysville, Ohio, which is part of Honda hydrogen business strategy that includes Class 8 trucks.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreRead Next

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More