Sensors for Composites Processing: CW Trending Episode 8

Why use sensors in composites manufacturing? What sensor types are available and how can they be applied? Learn about all of this and more in a discussion with CW senior editor Ginger Gardiner and editor-in-chief Jeff Sloan in this episode of CW Trending, sponsored by RVmagnetics.

Share

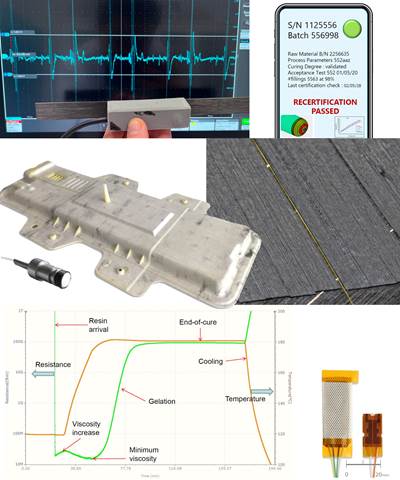

In this episode of CW Trending, sponsored by , CW senior editor Ginger Gardiner and editor-in-chief Jeff Sloan discuss the use of sensors in composites manufacturing to optimize processes, reduce cycle time and waste, and improve part quality and sustainability. Ginger presents slides reviewing a variety of different sensor technologies and case histories in composites. She also explains how these technologies are not only enabling the digital twin and intelligent manufacturing, but also opening new possibilities for composites, such as thermoplastic-overmolded thermosets and sensing structures that can incorporate, for example, haptics allowing the captain of an 81-meter yacht to steer more efficiently by feeling and reacting to actual ocean loads on the composite rudder.

Want to learn more about sensors? Check out our microsite!

Related Articles:

Fingerprinting liquids for composites

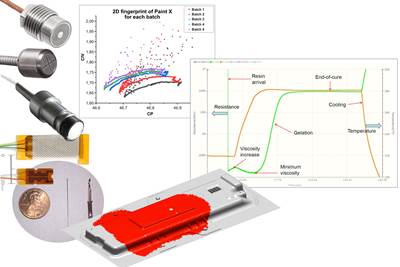

Collo (Collo, Tampere, Finland) uses electromagnetic sensors and edge analytics to optimize resin degassing, mixing, infusion, polymerization and cure as well as monitoring drift from benchmarked process parameters and enabling in-situ process control.

In-situ composites sensors for increased production rates, smart processes and life cycle monitoring

Com&Sens FBG sensors are embedded into pressure vessels, rudders and bridges, with new edge and surface connection technology, aimed at cost-effective serial production and monitoring of composite structures.

Customizing ultrasonic sensors for composites process optimization and control

University of Augsburg developed sensors for the CosiMo project’s digital twin and closed-loop process control of EV battery box cover demonstrator, and now moves forward with the AI Production Network for industry collaboration.

Artificial intelligence optimizes CNC milling of carbon fiber-reinforced composites

The Augsburg AI Production Network — DLR Center for Lightweight Production Technology (ZLP), Fraunhofer IGCV and University of Augsburg — use ultrasonic sensors to correlate sound to quality in composites machining.

Contactless measurement of temperature, pressure in composites

Magnetic microwires enable contactless measurement of temperature and pressure during cure and in service.

Combining AC and DC dielectric measurements for cure monitoring of composites

Lambient Technologies (Cambridge, Ma, U.S.)advances dielectric analysis (DEA) for more reliable, affordable composites manufacturing.

Read Next

Discover More About Sensors for Composites Processing

Throughout 2020 and 2021, CW has reported on sensors that can be used to process composites, as well as projects that demonstrate their installation and capabilities. This microsite collates CW’s reporting on sensors to provide, in one place, information about the types of sensors being used in composites.

Read MoreSensors: Data for next-gen composites manufacturing

In the quest for sustainability, sensors are reducing cycle times, energy use and waste, automating closed-loop process control and increasing knowledge to open new possibilities for intelligent manufacturing and structures.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More