VIDEO: Robots enable nine-axis machining of composites

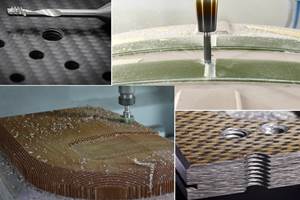

Machine Tool Camp displayed its hybrid machining center at CAMX, featuring nine-axis machining capability enabled by robotics.

Share

During CAMX 2024, ÂÌñÏ×ÆÞ spoke with Scott Kauphusman, president of (Eau Claire, Wis., U.S.), about the company’s work to develop hybrid machining centers.

These centers use robots to perform nine-axis machining and finishing of composites in ways the company says are not possible with traditional five-axis CNC machines.

One benefit of nine-axis machining is ease of access to a part, which enables undercuts and under features without rotating the part.

Related Content

-

Seven tips for machining composite aerospace components

Machining composite materials is a dusty, arduous and abrasive process that is hard on cutting tools, requiring the right combination of strategies and know-how to properly navigate their dynamics.

-

Developing milling for CMC because grinding takes too long

Economical processes that can cut machining time by 70% are being tested on aeroengine turbine blade demonstrators by Hufschmied and DLR in the SCANCUT project.

-

VIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with ‪Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

Related Content

Seven tips for machining composite aerospace components

Machining composite materials is a dusty, arduous and abrasive process that is hard on cutting tools, requiring the right combination of strategies and know-how to properly navigate their dynamics.

Read MoreDeveloping milling for CMC because grinding takes too long

Economical processes that can cut machining time by 70% are being tested on aeroengine turbine blade demonstrators by Hufschmied and DLR in the SCANCUT project.

Read MoreVIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with ‪Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

Read MoreOptimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

Read MoreRead Next

VIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with ‪Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreComposites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

Read More