VIDEO: Recycling and machining carbon fiber scraps

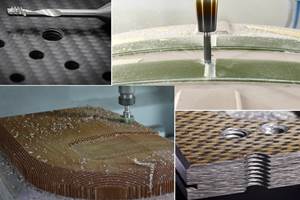

Elevated Materials has partnered with ‪Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

Share

Scott Francis, editor-in-chief of ÂÌñÏ×ÆÞ, spoke with Ryan Olliges, founder and president of Elevated Materials (Gardena, Calif., U.S.) at CAMX 2024 about the company’s innovative approach to recycling carbon fiber scraps.

Elevated Materials has partnered with Toray Composite Materials America, Inc. (Tacoma, Wash., U.S.) to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills. This method, which includes compression molding uncured prepreg scraps, is proving more cost-effective and efficient than traditional laminate production.

Elevated Materials aims to divert 50,000-100,000 pounds of carbon fiber scraps from landfills this year, transforming it into useful stock material.

Helpful links:

Related Content

-

Optimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

-

Thermwood unveils MAX5 large-scale CNC

Heavy-duty, high-clearance, five-axis CNC router is built to perform in extreme composites machining environments.

-

Zimmerman highlights five-axis portal milling line

The FZU22 machines various workpiece shapes, sizes and materials including carbon fiber and other fiber reinforcement options.

Related Content

Optimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

Read MoreThermwood unveils MAX5 large-scale CNC

Heavy-duty, high-clearance, five-axis CNC router is built to perform in extreme composites machining environments.

Read MoreZimmerman highlights five-axis portal milling line

The FZU22 machines various workpiece shapes, sizes and materials including carbon fiber and other fiber reinforcement options.

Read MoreAddressing rivet hole drilling challenges for aerospace composites

Kennametal explores technological advancements in composite drilling, including stacked laminates, to meet aerospace applications and sustainability challenges.

Read MoreRead Next

VIDEO: Painting parts with self-learning robots

LestaUSA’s self-learning robots on display at CAMX 2024 enhance composites manufacturing workflow and workforce needs.

Read MoreComposite Kape skateboard delivers durability, pop

Collaborative effort between KraussMaffei and entrepreneur Peter Karacsonyi led to the Vanguard, an in-situ polymerized board comprising fiberglass sandwich composites with a recyclable polyamide.

Read MoreReFrame project commits to recyclable CFRP aircraft structure research

German inter-university network HP CFK is investigating recyclable sandwich structures, developing sustainable mobility concepts for applicability in safety-critical aircraft components.

Read More