Textile machinery, NCFs provide sustainable processing options

CAMX 2024: Karl Mayer is returning to CAMX with a focus on fabric- and fiber-handling equipment, in addition to its application development services.

Share

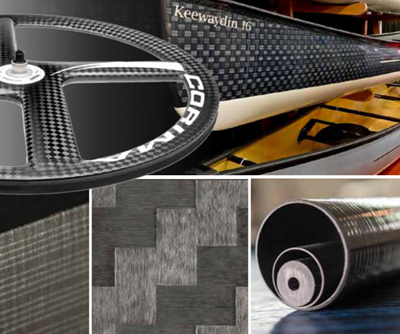

Source | Karl Mayer North America

After a brief hiatus, noncrimp fabric (NCF) production specialist Karl Mayer North America (Greensboro, N.C., U.S.) is returning to CAMX. The Karl Mayer Group (Obertshausen, Germany) subsidiary is presenting itself as an innovative composites partner with the display of high-performance machines such as the Cop Max 4, a flexible all-rounder made to produce multilayer, multiaxial fabric structures; the Cop Max 5, specifically for processing carbon fibers; and the UD 700 fiber spreading system. Furthermore, the company is highlighting a new machine that was launched this past spring, called Max Glass Eco, for highly productive manufacturing of standard applications made exclusively from glass fiber.

Overall, the focus of the company’s medial presentation — the various medias on display at the booth — focus on the processing of natural fibers into sustainable composite reinforcements, from videos to final products made from natural fibers, as well as a sample collection. For instance, in cooperation with winter sports industry representatives, Karl Mayer has processed hemp tapes and flax fibers into NCFs for snowboards and skis using the Cop Max 4, which were launched at JEC World 2024 and Techtextil visitors.

“The global composites industry is under enormous pressure to reduce its ecological footprint,” says Lutz Heinig, sales manager technical textiles, Karl Mayer North America. “Our NCFs made from natural fibers can make an important contribution to this.”

Related Content

-

Maximize your experience: CAMX 2025 exhibit previews, Part 1

This list of 90+ exhibitor previews solicited by CW offers a glimpse into the various technologies, emerging trends and solutions attendees should look for on the CAMX show floor.

-

New brand identity launch aligns with nonwoven portfolio offerings

CAMX 2024: James Cropper, formerly known as Technical Fibre Products, is bringing its new name to the U.S. composites industry, highlighting its specialization in carrier, surface and fire protection veils, among other products.

-

Repurposed carbon fiber waste support closed-loop recycling goals

CAMX 2025: Work with Carbon Fiber Conversions, a supplier and a strategic partner, to transform carbon fiber waste into a valuable resource, strengthening both business and sustainability credentials.

Related Content

Maximize your experience: CAMX 2025 exhibit previews, Part 1

This list of 90+ exhibitor previews solicited by CW offers a glimpse into the various technologies, emerging trends and solutions attendees should look for on the CAMX show floor.

Read MoreNew brand identity launch aligns with nonwoven portfolio offerings

CAMX 2024: James Cropper, formerly known as Technical Fibre Products, is bringing its new name to the U.S. composites industry, highlighting its specialization in carrier, surface and fire protection veils, among other products.

Read MoreRepurposed carbon fiber waste support closed-loop recycling goals

CAMX 2025: Work with Carbon Fiber Conversions, a supplier and a strategic partner, to transform carbon fiber waste into a valuable resource, strengthening both business and sustainability credentials.

Read MoreVIDEO: Robots enable nine-axis machining of composites

Machine Tool Camp displayed its hybrid machining center at CAMX, featuring nine-axis machining capability enabled by robotics.

Read MoreRead Next

The spread of spread tow

Advancing from “lighter and thinner” to boosting strength, stiffness, impact resistance and productivity, spread tow unlocks new applications and markets.

Read MoreHealable thermoset resin achieves ultra-fast composites repair

CAMX 2024: CompPair HealTech solutions give the ability to heal cracks and delaminations in a composite via local heating more than 60 times, available for a range of composite processes.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More