Polymer systems facilitate architectural, structural repair and protection

CAMX 2024: ChemCo Systems’ products are designed to install, protect or repair concrete, steel, wood as well as composite systems.

Share

Source | ChemCo Systems

(North Fair Oaks, Calif., U.S.), a division of American Polymers Corp., manufactures a diverse selection of highly durable polymer systems for use in civil infrastructure and construction repair applications.

Founded in 1993 by the same experienced technical staff who developed the SCB system of structural crack repair at Adhesive Engineering, ChemCo’s products are designed to install, protect and repair architectural and structural concrete, as well as bond and protect substrates including steel, wood, and carbon and glass fiber composite systems.

ChemCo Systems’ products are available for: structural crack repair, anchor bolts, coatings and sealants for corrosives, machine bases, old-to-new pours, joint nosing, control joint filling, seismic upgrades, plate bonding reinforcement, spall and void repair, underwater (marine) and extreme environments including coatings that can protect against concentrated sulfuric acid spills.

ChemCo Systems offers an experienced technical service and R&D team to provide customers with quick responses and the ability to customize products for difficult applications. The company’s in-house testing lab is well equipped to handle most AASHTO, ACI, ASTM, CSI, DOT, ICRI and International standards. Recent innovations include:

- InsulPOX for protecting plant environments, reducing explosion and cold cloud hazards from spills of cryogenic liquids including LNG, H², O², N², Ar, He and the new clean fuel, green H²

- Acrylic, polyurea and epoxy line striping for pavements

- High friction surface treatment (HFST) epoxies for highways

- Street demarcation technologies using colored recycled glass for smart cities

- Ambient temperature EA (1:1) tack coat and repair binder.

ChemCo Systems’ product lines are manufactured in strategic locations across the U.S., including the states of California and Texas, and Chicago and Atlanta. Substantial inventory of raw materials and finished goods are maintained to serve contractor needs quickly, particularly during unpredictable shortages.

Related Content

-

Healable thermoset resin achieves ultra-fast composites repair

CAMX 2024: CompPair HealTech solutions give the ability to heal cracks and delaminations in a composite via local heating more than 60 times, available for a range of composite processes.

-

South Asia wind park applies We4Ce, CNC Onsite tech for composite blade root remanufacturing

This on-site “Re-FIT” method eliminates the need for off-site transport, reducing blade waste, saving 60% in cost and finding a precision solution when drilling out defective bushings from fiberglass blades.

-

Microvascular channel-forming technique optimizes self-healing, thermal management implementation

Several patents by the University of Cukurova highlight a novel method for more easily forming microvascular channels in composite structures, opening the path for self-repair capabilities in a variety of industry applications.

Related Content

Healable thermoset resin achieves ultra-fast composites repair

CAMX 2024: CompPair HealTech solutions give the ability to heal cracks and delaminations in a composite via local heating more than 60 times, available for a range of composite processes.

Read MoreSouth Asia wind park applies We4Ce, CNC Onsite tech for composite blade root remanufacturing

This on-site “Re-FIT” method eliminates the need for off-site transport, reducing blade waste, saving 60% in cost and finding a precision solution when drilling out defective bushings from fiberglass blades.

Read MoreMicrovascular channel-forming technique optimizes self-healing, thermal management implementation

Several patents by the University of Cukurova highlight a novel method for more easily forming microvascular channels in composite structures, opening the path for self-repair capabilities in a variety of industry applications.

Read MoreFACC signs multiyear agreement with Pratt & Whitney for fan case MRO

FACC is growing its component repair services with the repair and overhaul of its customer’s composite PW800 turbofan engines.

Read MoreRead Next

Composites end markets: Infrastructure and construction (2024)

Composites are increasingly used in applications like building facades, bridges, utility poles, wastewater treatment pipes, repair solutions and more.

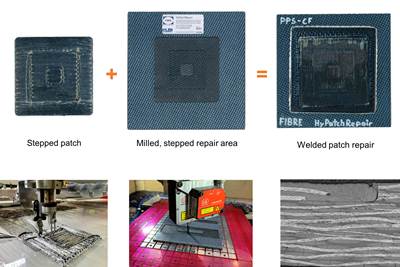

Read MoreDeveloping repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More