Formable, reusable tooling achieves complex composite parts

CAMX 2024: Hawthorn Composites is displaying an inner and outer tail boom and a multi-chamber composite trailing edge control surface, enabled via its Smart Tooling solution.

Share

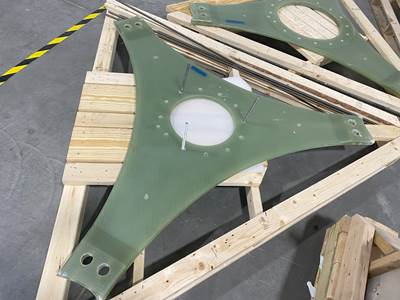

PAL-V layup. Source (All Images) | Hawthorn Composites and Smart Tooling

Hawthorn Composites and Smart Tooling (Miamisburg, Ohio, U.S.) is exhibiting multiple displays — including a sub-scale trailing edge and tail booms — that demonstrate its ability to produce high-quality, complex composite parts with Smart Tooling.

The first display includes the inner and outer tail boom for the PAL-V Liberty flying car, made by Hawthorn Composites. The tail booms are complex geometry composite parts with trapped features and some high-tolerance requirements, developed using carbon fiber prepreg laid up on Smart Tools using laser guidance. Once layup was completed, the Smart Tools were placed into cure molds and cured in a conventional oven; Hawthorn says they act like bladders during cure and were pressurized to drive out air and compact the laminate during the cure cycle.

The second display is a sub-scale, multi-chamber composite trailing edge control surface that was a proof of concept (POC) project for Pilatus Aircraft Ltd. (Stans, Switzerland). Results led to Pilatus adopting a similar method of manufacture for making the control surfaces for its PC-24 business jet.

Pilatus trailing edge.

The small trailing edge chamber of the control surface has an acute, knife edge angle that would traditionally be made using a fabricated foam core. For this POC control surface, however, the trailing edge chamber and the adjoining chamber were made using Smart Tools. The fabrication included laying up carbon fiber prepreg into a floating lid cure mold, laying up prepreg onto the Smart Tools and placing them into the cure mold. Once completed, cure was performed via autoclave.

The Smart Tooling technology enables a rigid, reusable, elastic and reformable mandrel that can ease the burden of layup, while still enabling simplicity of extraction from the cured, trapped or complex geometry composite part.

Related Content

-

Exploring powder coating for composites

Advancements in powder coating technology make it a viable surface finish for a growing number of composite applications.

-

Innovations deliver improved composite bonding, sealing and structural reinforcement

JEC World 2025: L&L Products is exhibiting newly announced and proven technology solutions for composites fabricators, addressing core, adhesive and sealant needs.

-

Environmentally friendly composites polymerization initiator

CAMX 2025: The phthalate- and solvents-free Akperox ST-CL200 presented by AKPA Chemicals provides a reliable, user-friendly polymerization alternative while enabling high-performance production processes.

Related Content

Exploring powder coating for composites

Advancements in powder coating technology make it a viable surface finish for a growing number of composite applications.

Read MoreInnovations deliver improved composite bonding, sealing and structural reinforcement

JEC World 2025: L&L Products is exhibiting newly announced and proven technology solutions for composites fabricators, addressing core, adhesive and sealant needs.

Read MoreEnvironmentally friendly composites polymerization initiator

CAMX 2025: The phthalate- and solvents-free Akperox ST-CL200 presented by AKPA Chemicals provides a reliable, user-friendly polymerization alternative while enabling high-performance production processes.

Read MoreHigh-quality heat treatment, lab equipment for simplified operation

CAMX 2024: Across International is showcasing an array of heat and laboratory materials, including drying ovens, high-temperature furnaces and a bladeless mixing solution.

Read MoreRead Next

Building a better tail boom

Out-of-autoclave carbon fiber/thermoplastic demonstrator is a 30 percent lighter drop-in replacement for an existing aluminum design.

Read MoreRTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More