Search Results

Showing 11 – 20 of 41 results

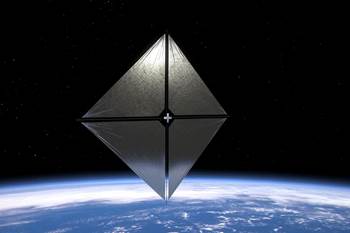

NASA ACS3 system made of flexible polymer and carbon fiber materials has successfully deployed its boom system, shows potential for future space operations.

Sunlight-based propulsion system, supported by carbon fiber-reinforced booms, will undergo weeks-long testing to demonstrate and verify its capabilities.

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

RWC built and delivered solar array substrate panels from trace/lead-integrated skins that enable direct integration with solar cells, saving weight and time.

CFRP has become key to targeting efforts in reusing components like rocket stages, as well as the development of reusable hypersonic testbeds and spaceplanes, for increasing space commercialization.

GTNANO ANT, validated through multiple Phase I-III SBIR/STTR projects, are compatible with a wide range of composite materials and processes, demonstrating ILSS, toughness and fatigue resistance.

Collaboration with UAE private aerospace company will bring 3D-printed Windform composite materials to development of the Lunaris moon mission payload.

Despite political and supply chain challenges, renewable and nuclear energy continue to grow in use. Composite materials enable current and future energy technologies across sectors.

The lunar lander, complete with Type 5 pressure vessels, was deployed on Feb. 15 for testing the lunar environment in preparation for future NASA Artemis landers.

The agency’s Orion spacecraft — showcasing an abundance of composite components and structures — launched 1:47 a.m. on Nov. 16, and is on its way to the moon as part of the Artemis program.