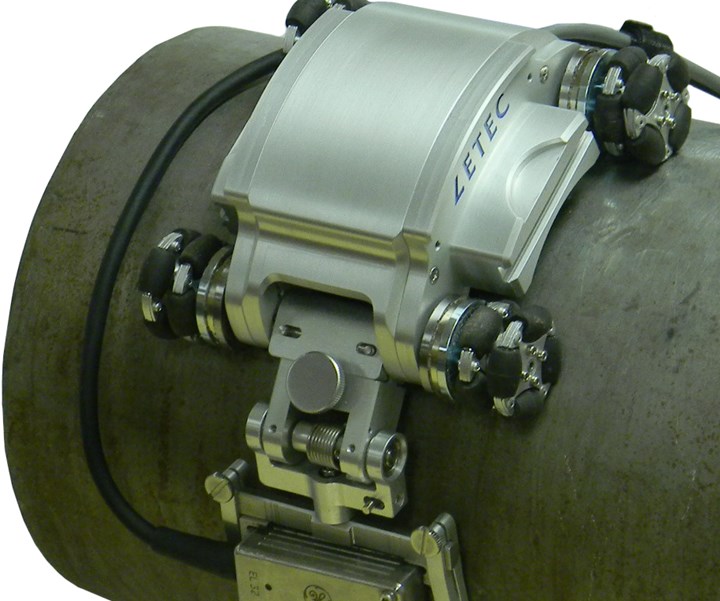

Zetec scanner designed for versatile ultrasonic testing

The versatile, manual 2D encoded scanner is designed for ultrasonic inspections of oil and gas, aerospace and other applications.

Source | Zetec

Zetec Inc. (Snoqualmie,Wash., U.S.) has introduced its NDT Sweeper Scanner, designed to be a versatile manual 2D encoded scanner for ultrasonic inspections for oil and gas, aerospace and other applications.

NDT Sweeper has two integrated encoders for precise 2D scanning. It can support up to two phased array probes at once for pitch-catch ultrasonic inspections, and the individual probe suspension can be fixed axially or laterally to meet specific needs. The scanner is said to be simple to deploy, able to encode in raster scan across long distances and able to provide C-Scan mapping of large components.

Source | Zetec

NDT Sweeper features non-marring wheels with integrated magnets designed for safe and effective use on various materials, including composites. The wheels are optimized for easy movement in the scan and index directions.

The scanner is designed to be compact, lightweight and ergonomic, and is said to be suited for ultrasonic inspections ranging from long-seam welds to corrosion mapping and more. It is intended to eliminate the need for multiple specialized scanners, reducing equipment costs, and is deployed with a TOPAZ portable ultrasonic instrument and UltraVision software.

Related Content

-

Shearography equipment well suited to composites NDT

CAMX 2025: Laser Technology Inc. features analysis tools like the LTI-2100 and LTI 5200, which are optimal for detecting subsurface composite flaws.

-

Radalytica advances multimodal 3D robotic scanner for composites, future aircraft inspection

Radalytica continues to develop its RadalyX nondestructive testing (NDT) system, merging diverse imaging methodologies for inspection in laboratories to aircraft hangars.

-

Xnovo Technology, Exciscope introduce X-ray tensor tomography technique

Through a strategic partnership, the companies introduce the FiberScanner3D module, dedicated to bringing more rapid, reliable and robust fiber structure characterization methods to lab settings.

.jpg;width=70;height=70;mode=crop)