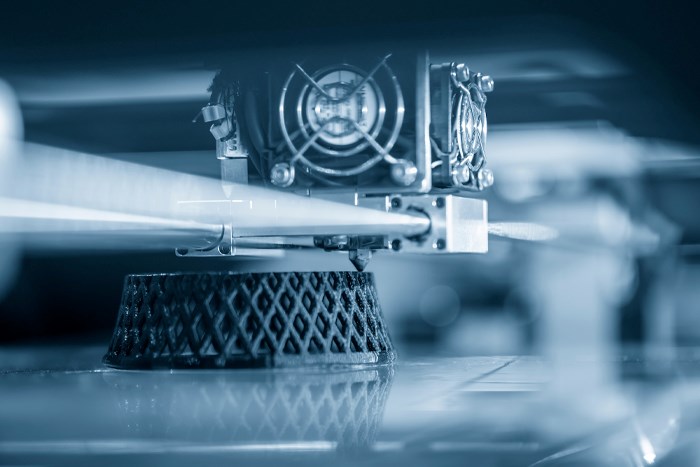

Xenia Materials reveals composite materials for FDM printing

A new range of 3D printing materials are formulated for use on any pellet-based fused deposition modeling printer.

Photo credit: Xenia Materials

(Mussolente, Italy) has announced a new range of 3D printing materials, comprised of resins combined with chopped fibers and additives. The materials are made for use in any pellet-based fused deposition modeling (FDM) printer, for large-scale additive manufacturing (LSAM) as well as high-precision production.

Xenia will offer materials dedicated to 3D printing based on its existing range of product families: Xecarb, Xebrid, Xelight and Xegreen. The Xecarb 3DP brand includes carbon fiber-reinforced PEI, ABS and PC. Xebrid 3DP includes a glass and carbon fiber-reinforced ABS. Xelight 3DP includes a lightweight polyether block amide (PEBA), and Xegreen 3DP includes carbon fiber-reinforced PA6 and PA66. According to Xenia, the materials are recyclable and suitable for a wide range of applications and markets including industry, sport, sustainable mobility and defense.

Related Content

-

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

-

Active core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.