The Gill Corp. announces novel Gillcore HF fiberglass honeycomb core

High-temperature fiberglass-reinforced phenolic honeycomb core meets all AMS 3715 requirements with optimized moisture resistance.

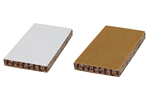

Photo Credit: The Gill Corp.

The Gill Corp. (TGC, El Monte, Calif., U.S.) announces the new fiberglass honeycomb core, which, developed in response to industry demand from aerospace customers, meets all AMS 3715 requirements. The core is produced with a substrate consisting of woven fiberglass cloth reinforced with heat-resistant phenolic resin for improved moisture resistance over traditional aramid fiber substrates. TGC says it is suitable for high-temperature applications requiring a high degree of forming and high moisture areas.

TGC processes rolls of fiberglass cloth through the same manufacturing equipment as aramid honeycomb cores. In addition to completing its own AMS 3715 test requirements, the company is working with other customers to meet their own qualifications.

Testing performed includes:

- Plate shear strength and modulus, ribbon and transverse.

- Stabilized compression strength and modulus.

- Flatwise tension.

- 65F, RTA, 180F, 250F, 350F

- Wet – RTA, 180F, 250F, 350F.

Related Content

-

High-tension, vertical filament winding enables affordable flywheel energy storage system

French startup Energiestro’s prototype solar energy flywheel-based storage system aims to reduce costs with glass fiber composites and prestressed concrete.

-

Polaris Spaceplanes receives MIRA II, MIRA III fiberglass airframes

German aerospace startup prepares next demonstrators toward reusable space launch and hypersonic transport toward routine, low-cost and safe access to space.

-

Al Seer Marine, Abu Dhabi Maritime unveil world’s largest 3D-printed boat

Holding the new Guinness World Record at 11.98 meters, the 3D-printed composite water taxi used a CEAD Flexbot to print two hulls in less than 12 days.