Fortify Flux 3D printers optimize fiber alignment, enhance properties for tailored composites

Systems combine mixing magnetics and digital light processing (DLP) 3D printing to enhance composite microstructures and develop high-performance, low-cost components.

All photo credit: Fortify

3D startup company (Boston, Mass., U.S.) has recently expanded its Flux 3D printer series, which now includes the Flux One, Flux Core and Flux 3D. In particular, the Flux One and Flux 3D use Fluxprint, a patented process that combines magnetic fields and digital light processing (DLP), to optimize the functionality of 3D-printed, fiber- and particle-filled photopolymers. Fillers include glass, carbon and ceramic fibers as well as engineered plastics like nylon and ultra-high molecular weight polyethylene (UHMWPE). Digital tooling, low loss resin formulations and ESD materials are also applied.

All Fortify 3D printers employ CKM (Continuous Kinetic Mixing), which targets the mixing, heating and recirculating of resins. This ensures that incorporated additives — which enhance mechanical performance such as strength, stiffness, toughness, wear and heat deflection temperature — stay uniformly distributed throughout the material while mitigating sedimentation and aggregation. CKM also enables the processing of high- viscosity materials.

Additionally, Fortify’s magnetic fiber alignment technology, Fluxprint, offers more control of particle orientation for greater thermal, mechanical and electrical properties.

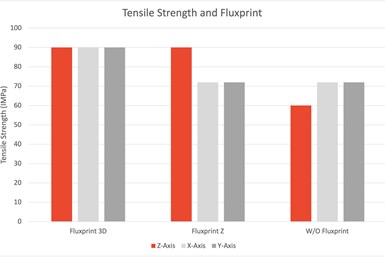

Graph compares the same material across Fortify’s three 3D printing systems using Fluxprint..

The Flux One and Flux 3D systems incorporate Fortify’s magnetic alignment technologies. Configured with the Fluxprint Z magnetic field, Flux One retains z-axis fiber alignment capabilities, which are said to overcome the challenges of z-axis anisotropy in 3D printing. Applications include robust mold tooling, jigs and fixtures. Alternately, the Flux 3D incorporates Fluxprint 3D, a three-axis magnetic field that gives the ability to selectively align fibers in any orientation. Applications include heat sinks, heat exchangers and high-performance industrial connectors.

Tests comparing the same material across Fortify's 3D printers with different versions of Fluxprint (depending on the printer) indicated a tensile strength of 90 MPa in the z-axis for both Fluxprint Z and 3D configurations, compared to a tensile strength of 50 MPa without Fluxprint.

Related Content

-

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

-

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

-

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.