ExOne launches comprehensive industrial-grade, 3D-printed tooling solutions

X1 Tooling, reported to be the broadest portfolio available to manufacturers, offers fast, affordable and local tooling options for the final production of metal, plastic and composite designs.

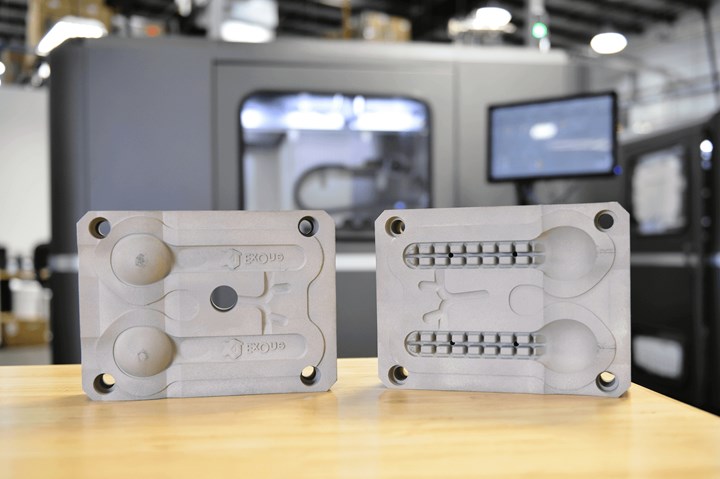

X1 MetalTool is shown for a plastic injection molding application in front of the X1 25Pro metal 3D printer. Photo Credit: Business Wire

(North Huntington, Penn., U.S.), a company that provides industrial sand and metal 3D printers using binder jetting technology globally, launches , what it says is the broadest portfolio of industrial-grade, 3D-printed tooling available, the X1 Tooling. The range now offers new solutions for plastic injection molding or forming, composites layup, casting metals and more.

In all, manufacturers are now able to leverage six new and affordable tooling applications from ExOne:

Composites production:

- X1 Layup: A 3D-printed sand form is infiltrated with a durable resin and coated for high-precision, high-temperature composite layup applications. X1 Layup offers dimensional tolerances of ± 0.025” and tooling can be precision machined to ± 0.005” if needed.

- X1 Washout: This 3D-printed sacrificial tooling washes out with tap water after traditional layup and autoclaving of composite materials, including carbon fiber. X1 Washout is a sand form 3D printed with a water-soluble binder and surface coated. Ideal for ducting, mandrels and other designs with trapped geometries.

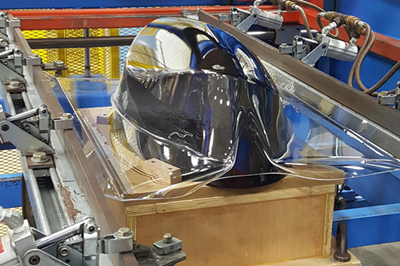

Plastic production:

- X1 MetalTool: This 3D-printed metal tooling option has passed preliminary tests to replace standard steel or aluminum tooling for plastic injection molding, blow molding and other plastic and foam forming applications. X1 MetalTool is available in 420i, a highly durable and affordable steel-bronze matrix, as well as 316L stainless steel, M2 tool steel and more. This tooling can be finish machined, acid etched and polished to a diamond finish, and is currently ideal for complex inserts. ExOne is currently seeking additional development partners to expand durability testing of this product line.

- X1 ThermoForm: A 3D-printed sand form is infiltrated with a durable resin and coated to create small- to large-format molds for a variety of thermoforming applications, such as vacuum forming, compression molds, foam molding and more.

Metal Production:

- X1 SandCast: For sand molds and cores for metalcasting. Sandcastings can be delivered in a variety of sand types and binders, including sustainable inorganic formulas for high-quality aluminum castings.

- X1 MetalTool: In addition to plastic forming applications, X1 MetalTool can also be used to directly 3D print end-of-arm tooling, and rugged perishable or consumable cutting tools in a variety of metals, including tool steels.

- X1 DieMold: Still in development, rugged die molds 3D printed in H13 tool steel are currently fast-tracked with several global manufacturers after passing proof of concept tests.

Manufacturers can now purchase X1 Tooling products directly from ExOne through the company’s ExOne Adoption Centers—or manufacturers can purchase a 3D printer for tooling applications.

Sizing options vary for the type of tooling as detailed below:

- All sand- and sand-infiltrated tools, which includes X1 ThermoForm, X1 Layup, X1 Washout, X1 SandCast, are produced in the build volume of ExOne S-Max series printers: 1,800 x 1,000 x 700 mm (70.9 x 39.4 x 27.6”). The printed sections can also be segmented and assembled together before epoxy infiltration to make even larger tools.

- Currently, all X1 MetalTool and X1 DieMold tools are 3D printed in an X1 25Pro build volume of 400 x 250 x 250 mm (15.75 x 9.84 x 9.84”), with development underway to 3D print tooling options in the X1 160Pro, which offers a build volume of 800 x 500 x 400 mm (31.5 x 19.7 x 15.8”).

Related Content

Optimized rib-reinforced hollow composites via printed molds

Addyx topology optimization and water-soluble mandrel enables simultaneous rib and skin layup for one-shot, high-strength, lightweight structures.

Read MoreAutomated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreTesting to support composite bolted joint analysis

An overview of ASTM Standard Guide D8509, and its coupon-level mechanical testing of design properties for analyzing composite bolted joints.

Read MoreRead Next

ExOne acquisition accelerates expansion into 3D-printed tooling for composites

Patented 3D-printed sand tooling solution from Freshmade 3D applicable for composite layup, vacuum forming, compression molds, with 30-50% cost savings and design flexibility.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More