CAMX 2020 exhibit preview: Janicki Industries

Janicki Industries is featuring its fast prototyping process for flyaway parts and tooling for urban air mobility (UAM) vehicle manufacturers.

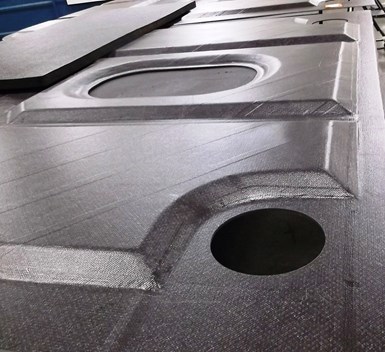

Carbon fiber production tool for aerospace parts. Source | Janicki

Janicki Industries (Sedro-Woolley, Wash., U.S.) is featuring its fast prototyping process for flyaway parts and tooling for urban air mobility (UAM) vehicle manufacturers. Specifically, the company highlights its use of large-scale, 5-axis milling to create large, precise, prototype tooling for the marine, defense and aerospace industries, and parts and tools produced for the aviation industry for more than 25 years. Within the more recent landscape of urban air mobility, Janicki says its fast prototyping process supports vehicle manufactures to test their latest concepts in real-world conditions.

Carbon fiber flyaway part for an aerospace application. Source | Janicki

The company has a dedicated 160,000-square-foot building that supports prototype fabrication, short runs and assembly of air vehicles, and its large-scale, 5-axis machining streamlines the manufacturing processes from concept to product. Janicki also mills shape foam, fiberglass, carbon fiber, aluminum, Invar and steel into complex shapes required for aerospace products.

The company says its newest parts facility is optimized for production quantities of carbon fiber parts, with more 90,000 square feet of plant space and equipped with an autoclave, core sculpting, a cleanroom, non-destructive testing equipment, furnaces, waterjet cutters and curing ovens. Janicki says it is Nadcap-certified for fly-away carbon fiber composite parts with a proven history supporting leading aerospace firms.

Related Content

-

Plant tour: Hexagon Purus, Kassel, Germany

Fully automated, Industry 4.0 line for hydrogen pressure vessels advances efficiency and versatility in small footprint for next-gen, sustainable composites production.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

.jpg;width=70;height=70;mode=crop)