CAMX 2019 exhibit preview: LyondellBasell

LyondellBasell is featuring its styrene-free materials that can be sourced in forms including SMCs, BMCs and engineered structural composites.

Source | LyondellBasell

At its first CAMX this year, LyondellBasell (Houston, Texas, U.S.) is featuring its enhanced compounding portfolio, which includes styrene-free materials that can be sourced in a variety of forms including sheet molding compounds (SMC), bulk molding compounds (BMC) and engineered structural composites. The materials reportedly deliver low out gassing, reduced volatile organic compound (VOC) emissions and low odor while being simple to process, reducing overall system costs. Other characteristics are said to include premium surface appearance for a high-end look and feel, and superior mechanical and thermal properties for high-demand automotive, electronics and construction applications.

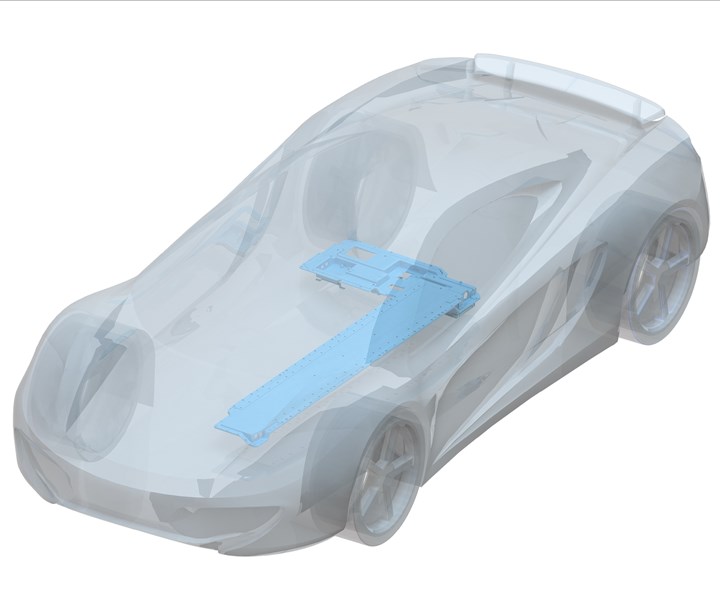

Also on display will be an electric vehicle (EV) battery tray made of Premi-Glas 1203-28, a low-shrink, high-strength SMC. Premi-Glas 1203-28 is said to deliver design flexibility, high mechanical performance, and low weight, critical characteristics for the EV market. This material reportedly allows for 3D molding with fast throughput and can be compression molded

A global plastics, chemicals and refining company, LyondellBasell's compounding portfolio includes performance brands Quantum Composites, BMCI, Premix and Tetra-DUR. The company says its products and technologies address issues such as energy storage, production and efficiency, reducing carbon footprint and weight reduction for improved performance. From materials utilizing bio-based feedstocks and recycled content to applications that are focused on addressing today’s emerging trends, the company’s solutions focus on sustainability and improving quality of life.

Related Content

-

Composite materials, design enable challenging Corvette exterior components

General Motors and partners Premix-Hadlock and Albar cite creative engineering and a move toward pigmented sheet molding compound (SMC) to produce cosmetic components that met strict thermal requirements.

-

WAG Wernli to produce composite brackets for Dufour Aero2 drone

The Swiss company was chosen for its C-SMC expertise, which will replace original aluminum brackets to enhance weight savings, corrosion resistance and adhesive bonding capabilities.

-

National Composites announces partners with compression toolmaker Laval

The new alliance will broaden National Composites’ capabilities in SMC and BMC and tooling, while providing customers with comprehensive solutions, from initial design to final delivery.

.jpg;width=70;height=70;mode=crop)