TRB Lightweight Structures manufactures prepreg material in-house to streamline part production

Company reaches 25,000-part milestone via rapid-cure prepreg technology.

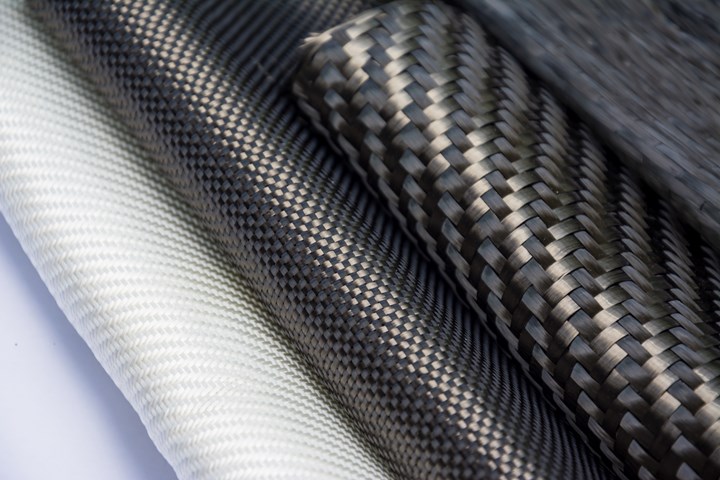

Photo Credit: TRB Lightweight Structures

TRB Lightweight Structures (TRB, Huntingdon, U.K.) announced on April 15 that it has begun manufacturing its own prepreg material to improve performance, cost and lead times for its composite parts. The company has already produced and shipped 25,000 parts using this proprietary, rapid-cure prepreg technology.

In late 2020, TRB announced a new production process to generate continuous fiber, thermoset composite parts at high volume for automotive markets. To deliver on that promise, the company built its own prepreg machines, and is developing a family of resins to support component manufacturing, including resins optimized for rapid cure, FST (UL94-V0) and high-temperature applications. TRB has emphasized that it is not selling its prepreg commercially, but is instead focused on streamlining its production process for the components it manufactures. This reportedly enables the company to decrease costs and lead times by reducing the number of vendors involved and eliminating minimum order quantities, while also improving manufacturing efficiency.

“By making our own prepreg, we are able to tune the material selection to precisely match what is needed for each customer,” says Andrew Dugmore, VP of business development at TRB. “We can create an optimal mix of fabric weight, colored surface finish and resin properties, as well as incorporating additional materials — such as EMI shielding, and electrical and thermal insulation — during the layup process.”

Related Content

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Bio-based, fire-resistant composites become mainstream

Projects use Duplicor prepreg panels with highest Euroclass B fire performance without fire retardants for reduced weight, CO2 footprint in sustainable yet affordable roofs, high-rise façades and modular housing.

-

Hybrid composite architecture enables rigid wind propulsion solution for maritime decarbonization

GT Wings’ AirWing leverages aerospace engineering principles combined with hybrid glass and carbon fiber composite construction to deliver up to 30% fuel savings through compact, deck-compatible wind propulsion.