Quickstep Technology selects JETCAM and CrossTrack for nesting and material tracking

In its final stages of JETCAM testing, Quickstep maintains its future expansion plans for Industry 4.0 functionality and a paperless factory.

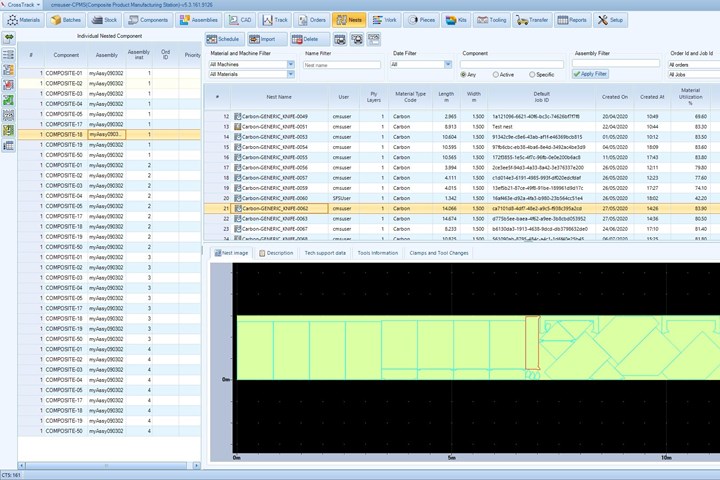

CrossTrack automatically imports orders for parts and generates NC code for multiple cutters with just a couple of clicks. Source | Quickstep Technologies

Quickstep Technologies (Bankstown, Australia), a global manufacturer of composite solutions for the defense and commercial sectors, announced on July 19 its selection and implementation of JETCAM Expert nesting and the CrossTrack composite manufacturing suite to manage nesting and prepreg composite location and life tracking for its facility in Bankstown, west of Sydney, Australia.

The company says it had initially identified potential improvements that could be made in nesting for their three CNC knife cutters, but after investigation, saw that additional benefits could be achieved in surrounding departments handling operations further on in the process, such as layup, tooling and at the autoclave.

“We were already investigating several nesting software systems, most of them limited only to nesting. We came across JETCAM in January 2020, after being recommended by an existing CrossTrack user and looked at the wider implications of such a system,” comments David Doral, chief technical officer (CTO) and head of engineering at Quickstep.

Quickstep says the project has been broken down into two phases — the first was to roll out CAD import and nesting in order to gain immediate benefits from the material efficiencies of JETCAM’s high-performance nesting. Phase two is said to expand CrossTrack to the shop floor, enabling staff to schedule nests for cutting, track layup tools and monitor the location and shop/shelf life of both raw material and kits around their facility. After performing a nesting benchmark comparison with several systems, Quickstep says it learned that the return on investment (ROI) in material savings alone would offer a payback in just six months for phase one of the project.

Quickstep’s preliminary results indicate a 3% savings in prepreg material consumption.

The decision to select CrossTrack was made in May 2020 based on both affordability and current and future functionality. Due to the coronavirus outbreak, Quickstep decided that both installation and training had to be performed remotely. The company says that JETCAM created a virtual environment, based on Quickstep’s CNC configuration, and generated and tested a replica installation in-house. Once proven, the software was installed and tested remotely the following month. Quickstep says the first test nest was produced within two hours of the first remote installation connection and further training provided online. A virtual machine was created on the same server with a replica of their JETCAM/CrossTrack setup, allowing Quickstep to plan and test the rollout of phase two in a duplicate environment without impacting their day-to-day operations and system configuration.

“The pandemic forced us to think about this implementation in an entirely new way, which will become a blueprint for future installations,” notes Martin Bailey, general manager of JETCAM International s.a.r.l. “We worked closely with Quickstep’s IT and engineering staff along with our own staff across multiple time zones to minimize the installation and configuration time online. The implementation was fast because CrossTrack is a standard off-the-shelf solution. It’s designed specifically for composite manufacturers and bridges the gap often left by financial-driven ERP system.”

Doral comments further on this point: “Remote installations across different time zones can be challenging and grind a project to a halt. JETCAM have been very responsive and flexible when providing training and support. Clear communication and transparency from both teams have been crucial in delivering a solution that not only suits Quickstep's needs but is on-time and budget.”

Phase 2 will extend CrossTrack to provide automatic roll allocation when nests are created and raw material/ply location and life tracking. Source | Quickstep Technologies

Quickstep says it also benefited from the JETCAM University — an online portal for customers providing hundreds of tutorial videos covering every aspect of the software. This allowed staff to back up their knowledge obtained through the online training with short videos focused on specific tasks.

As Quickstep had many legacy nests in DXF format that they wanted to import, they also took a short-term subscription of JETCAM Order Controller (JOC), which includes DXF splitting, which drastically reduced the work required to get the data into CrossTrack. Once split, the company was able to create a CSV file containing both individual ply and assembly (part) information and import them with just a few clicks.

Just two weeks after installing the software, the company is entering the final stage of testing, after which it will switch to CrossTrack to generate all of its nests. Quickstep’s preliminary results indicate a 3% savings in prepreg material consumption. These benefits, says Quickstep, will be applied to its main program, but the company is expecting to increase the magnitude of those savings when the system is applied to all its cutting operations. The company will then start the testing of phase two before rolling it out later this year. Investigation is already underway as to how CrossTrack might help with managing layup tools and scheduling for the autoclave.

“As part of our strategic plan to constantly drive operational improvements through new technology investment, we are looking at various options going forward, where CrossTrack will be integrated with our ERP system, provide Industry 4.0 functionality and help us enable a completely paperless shop floor. With the system already paying for itself in a few months on material savings alone, any further savings will go straight on the bottom line,” concludes Doral.

Related Content

IMDEA introduces digital twin for real-time analysis of composite materials production

Newly designed digital twin by IMDEA and Technical University of Madrid researchers enables manufacturers to see inside composite materials as they are being produced, facilitating early detection of faults.

Read MoreHow AI is improving composites operations and factory sustainability

Workforce pain points and various logistical challenges are putting operations resilience and flexibility to the test, but Industry 4.0 advancements could be the key to composites manufacturers’ transformation.

Read MoreUniSQ, iLAuNCH Trailblazer program drive digital twin innovation for composite repairs

Working with Boeing Australia, Memko and Dassault Systèmes, the University of Southern Queensland (UniSQ) has developed a digital twin via the 3DEXPERIENCE platform, digitizing processes that could lead toward more efficient and effective maintenance, repair and operations of future fleets.

Read MoreWichita State, Dassault Systèmes open Manufacturing Innovation Center

Aviation companies of all sizes will be able to improve their resilience and efficiency via the center’s virtual design, automation and additive manufacturing capabilities.

Read MoreRead Next

Ceramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More