LeMond Carbon audits rapid-oxidation carbon fiber technology

A Bureau Veritas audit of LeMond Carbon’s carbon fiber, made with a novel rapid-oxidation technology, shows mechanical properties comparable to Toray T300 fiber.

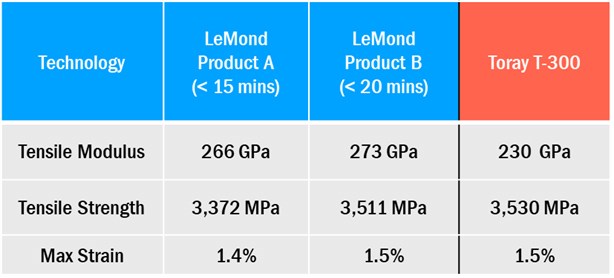

LeMond Carbon carbon fiber mechanical properties from Bureau Veritas audit. Source | LeMond

LeMond Carbon (Oak Ridge, Tenn., U.S.) announced on Dec. 12 the results of an independent technical audit conducted by Bureau Veritas (BV, Paris, France) of its rapid-oxidation carbon fiber manufacturing process. The audit was conducted on a pilot line at Deakin University’s Carbon Nexus facility in Geelong, Australia. LeMond says the total oxidation time and material properties verified by BV support LeMond’s claims to lower costs and significantly increased output versus traditional carbon fiber manufacturing technology.

Bureau Veritas offers laboratory testing, inspection and certification services and audits innovative technologies and manufacturing processes. For the audit of LeMond’s technology, BV measured total oxidation times of sub-15 and sub-20 minutes over two separate production campaigns of 24K standard modulus (SM) carbon fiber, achieving fiber tow properties in excess of 270 GPa tensile modulus and 3,500 MPa tensile strength (see table).

The BV audit was conducted on Carbon Nexus’s 100-metric-ton (nameplate) pilot line which is currently producing samples for trials with LeMond’s target customers in several industrial markets that consume standard modulus carbon fiber. In addition to accurately measuring oxidation times and assuring process traceability, BV oversaw the fiber sampling, packaging and shipping of audit samples for testing at BV laboratories in Pessac, France. Composite tow tests of the LeMond fiber were completed according to ASTM D 4018-17 standards.

LeMond and Deakin University are teamed to commercialize this rapid-oxidation technology, which enables reductions of 75% and 70% in capex and energy consumption per kilo of output respectively. LeMond says the rapid-oxidation process enables the company to produce carbon fiber with the lowest embodied energy of any standard PAN-based carbon fiber available today.

“This is a significant milestone for our company. Having our technology independently verified by BV validates the revolutionary nature of our technology,” says Greg LeMond, founder and chairman of the board of LeMond Carbon. “My team and I are excited to bring our high-performance, low-cost carbon fiber to the global market, and look forward to expanding into new markets where the current high cost of carbon fiber has been a significant barrier to adoption.”

“Deakin has always been excited about the potential of our patented new technology and it is encouraging to receive independent validation that our technology is effective at scale. We look forward to continuing to support LeMond as they commercialize a lower-cost and lower-emission carbon fiber,” says Derek Buckmaster, director Carbon Nexus.

Having proven the capability to successfully produce a competitive standard modulus carbon fiber, LeMond has launched a new capital campaign to develop a 5,400-metric-ton (nameplate) production facility in Oak Ridge. To date, parent LeMond Companies LLC has raised approximately US$18.6 million of seed capital from individual and institutional investors, including Deakin University

Founded in 2016, LeMond Carbon Inc. is commercializing carbon fiber manufacturing technology under a global 20-year license from Deakin University. It is currently operating a pilot scale carbon fiber manufacturing line located at Deakin University’s Carbon Nexus facility in Geelong, Australia. Upon expected commencement of operations in 2021, LeMond Carbon intends to produce and sell carbon fiber composite products to the wind, aerospace, oil and gas and auto industries.

For more information about LeMond and its carbon fibers, contact the company at press@lemondcarbon.com.

Related Content

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MorePrepreg compression molding supports higher-rate propeller manufacturing

To meet increasing UAV market demands, Mejzlik Propellers has added a higher-rate compression molding line to its custom CFRP propeller capabilities.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreLow-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreRead Next

Next-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More