Lanxess, Kautex Textron explore D-LFT for EV battery housings

Research cooperation substitutes steel and aluminum with a continuous fiber-reinforced thermoplastic technology demonstrator for advantages in weight, functional integration and mass production.

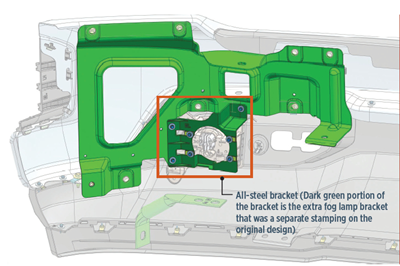

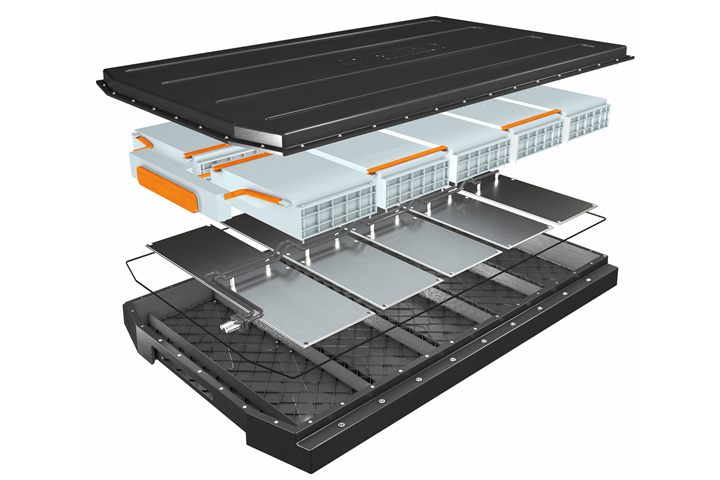

The demonstrator was developed based on the battery housing of a C-segment electric vehicle (EV). It consists of a housing tray with crash structure, a housing cover and an underrun (underbody) protection. Photo Credit: Kautex Textron GmbH & Co. KG

Specialty chemicals company Lanxess (Cologne, Germany) and Kautex Textron GmbH & Co. KG (Bonn, Germany), a Textron Inc. (Providence, R.I., U.S.) company, have been collaborating for several years to demonstrate the advantages of technical thermoplastics over metals in battery housings for electric vehicles (EVs) in terms of weight and cost reduction, functional integration and electrical insulation behavior Together, the companies have developed a near-series technology demonstrator in the feasibility study. With a length and width of around 1,400 millimeters each, the system is a large-format all-plastic housing part with a weight in the mid-double-digit kilogram range.

“As a first step, we have completely dispensed with the use of metallic reinforcement structures while proving we can commercially produce these complex, large components,” explains Felix Haas, director, product development, at Kautex Textron. Going forward, Kautex and Lanxess want to use the results of the cooperation to enter into development projects for series production with automotive manufacturers.

The demonstrator was developed based on the battery housing of a C-segment EV. It consists of a housing tray with crash structure, a housing cover and an underrun (underbody) protection. The housing components can be produced in a single-stage, direct long fiber thermoplastic (D-LFT) molding process. Lanxess has optimized its Durethan B24CMH2.0 PA6 resin as the material for the D-LFT molding compound; Kautex Textron compounds the PA6 for the process with glass fiber rovings. Lanxess’ Tepex dynalite continuous fiber-reinforced thermoplastic is applied as reinforcement for the housing structure. “The process enables shorter and thus more economical cycle times than the processes in which steel or aluminum are processed,” Haas explains.

Today, says Lanxess, housings for high-voltage batteries are primarily made of extruded steel or aluminum profiles. Depending on the vehicle class, the housing length and widths can be well over 2,000 or 1,500 millimeters, respectively. The size, the number of components and the numerous manufacturing and assembly steps make metal housings very cost intensive. For example, complex structures made from strand press profiles require many secondary work steps such as welding, punching and riveting. In addition, the metallic components must be protected against corrosion in an additional process step by cathodic dip coating.

“Plastics, on the other hand, can fully exploit their design freedom. By integrating functions such as fasteners and thermal management components, the number of individual components of a battery housing can be greatly reduced. This simplifies assembly and logistical effort, which reduces production costs,” says Dr. Christopher Hoefs, project manager e-Powertrain at Lanxess.

High-voltage battery housings must also meet a variety of highly demanding technical requirements, including high stiffness and strength, energy absorption in the event of a crash, flame retardancy and integration of the housings in the vehicle structure, to name a few. Lanxess reports that plastics have the potential to meet many of these needs. The material is corrosion resistant and electrically insulating, the latter of which ensures a reduced risk of the system short-circuiting. The low density of plastics and their potential for lightweight construction also lead to significantly lighter housings, which benefits, among other things, the range of EVs.

“We continue to work together on optimizing the production and structural design of the components. The aim is to carry out the majority of the development work virtually, in order to save costs in prototype design and to shorten the time to market of future series components,” Hoefs says.

Related Content

Plant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreDevelopment of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

Read MorePlant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.

Read MoreRead Next

Thermoplastic composites: Structural bumper bracket

Hybrid bracket reduces mass, increases design flexibility, package space in pickup front bumper.

Read MoreLanxess demonstrates Tepex composite material in structural bracket application

Lightweight bracket offers firm clamping of batteries in Mercedes-Benz S-Class with high strength under sustained dynamic stress, functional integration and no risk of short circuiting.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More