A digital approach to automation

One aerostructures manufacturer’s journey from hand layup to AFP.

Source | MRAS

Middle River Aerostructure Systems (MRAS; Baltimore, Md., U.S.), manufacturer of composite aerostructures for commercial and military use, decided several years ago that it wanted to improve its bottom line by automating its manufacturing process. The problem was, where to start? MRAS, which produces mostly nacelles and thrust reversers at its 1 million-square-foot Baltimore facility, was using mostly hand layup. However, the company knew that the next step was to invest in automation, which it hoped would eliminate the variability that comes with hand layup and reduce labor costs at the same time.

With the help of CGTech (Irvine, Calif., U.S.) and Electroimpact (Mukilteo, Wash., U.S.), MRAS began the process of analyzing a variety of available parts that could be redesigned using automation. The companies digitally modeled and simulated the manufacture of each of the candidate parts, enabling a thorough understanding of the cost versus savings. Mitchell Smith, composite process and technology leader at MRAS, notes that this was especially important given the small, relatively lightweight components that MRAS manufactures.

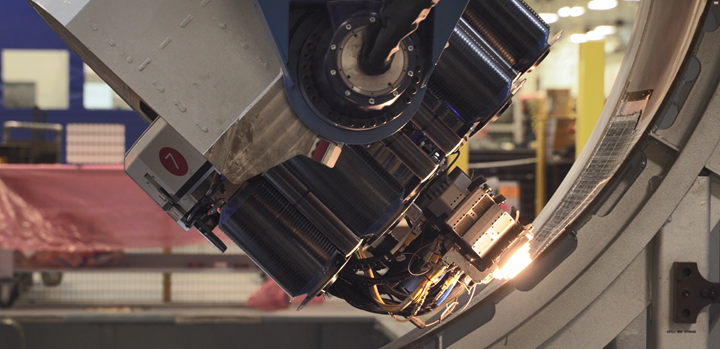

Shown here, an A320 NEO fixed gantry AFP machine cell. Source | MRAS

After several iterations, MRAS selected a group of parts to convert within the Airbus A320neo structures it was building. “The high volume and rate of the neo program enabled the cost versus savings equation to work out in favor of [automated fiber placement] AFP. We just had to stay within our cap ex [capital expenditure] targets,” explains Smith.

However, budget limitations meant that no new tooling could be purchased, and that only minimal floor space was available. This became the most complex part of the project, since MRAS was already in production using female tooling, while most AFP parts are made with male tooling that does not restrict the use of the large end effectors required to support the automated machinery. The geometry of male tooling is also favorable for material pay-out, which is controlled with tow tension.

“That was actually the biggest constraint,” Smith says. “We’d invested millions of dollars in female tooling and we were not going to purchase new tools — looking back, it presented a level of complexity that’s hard to appreciate. Male tooling would have made the machine easier to build and the processes easier to develop, but it also forced us to make big technology advancements quickly. In hindsight, that was a good thing, even if it didn’t seem that way at the time.”

“The bottom line was that we needed to be able to produce a high volume of relatively low-weight product at a high rate with a compact cell and a complicated tool string,” Smith notes.

Concurrently with the part selection process, MRAS also began evaluating various AFP machine builders. “We received a variety of machine proposals, and each had their pros and cons, but none matched up to the business case we needed to support,” says Smith. “In order to meet the business case, MRAS needed a high-speed AFP machine that supported a rapid tool change out and required minimal staff to run.”

Source | MRAS

Ideally, this machine would also — at least in theory — operate nonstop, with almost no downtime, to produce the more than 240 components that MRAS manufactures each month. “And even though they didn’t have one at the time, Electroimpact was the only company willing to work with us on building one,” Smith says.

Electroimpact’s roster of AFP and automated tape layup (ATL) machines rely on programming and simulation software from CGTech. After selecting the machine maker, MRAS spent the next year working with Electroimpact and CGTech to program and validate each component — multiple times, in some cases. As suspected, the U-shaped female tooling proved to be a tight fit for the AFP head, making accurate simulation critical to crash avoidance. Numerous trial components were made at Electroimpact, even before the machine was completely fabricated.

Toward the end of 2018, initial production began, and by the end of January 2019, MRAS was using its new automated process to manufacture nacelle components. Current production is reported to be at or above the planned business case, with significant reductions in labor costs and higher throughput.

Plus, MRAS emphasizes that it did not reduce its workforce by switching to automation. In fact, Smith says the opposite happened: “By bringing this new technology to the business, we have been able to capture new business and have installed additional AFP machines. We have had to hire additional people to handle the growth.” He concludes: “It was definitely the right move for us.”

Related Content

Industrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreFirst Airbus A350 crash confirmed in Haneda

Shortly after touch-down, a JAL A350-900 aircraft recently collided with a De Havilland Canada Dash 8. Exact circumstances are still unknown.

Read MorePlant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.

Read MoreRead Next

Evolving AFP for the next generation

‘Aerospace quality at automotive pace’ is the mantra of the supply chain being developed for next-generation commercial aircraft. Automation is evolving to meet the challenge.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More.jpg;width=70;height=70;mode=crop)