Aerospace

Inside R and D: A-VaRTM takes flight in Japan

Tests show out-of-autoclave process can reduce costs on new regional jet.

Read MoreIs it really low-tech vs. high tech?

I’ll bet that a lot of folks who read this column regularly — assuming I’m lucky and lots of folks are reading — have spent their entire careers working with E-glass without ever thinking they were high-performance geeks, too. To them, welcome to the club!

Read MoreLow-cost methods realize high-concept Superbus

Multifunctional mass-transport vehicle concept takes shape via resin-infused carbon/epoxy and vacuum-formed glass-reinforced thermoplastic sandwich construction.

Read MoreAircraft delays alter carbon fiber supply/demand balance

When Boeing announced in early December that it was officially pushing back the first flight and the first delivery of the 787 Dreamliner to second quarter 2009 and first quarter 2010, respectively, one of the first questions that circulated among our staff centered on the issue of carbon fiber supply.

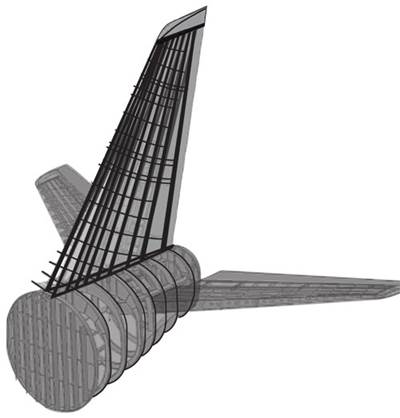

Read More787 integrates new composite wing deicing system

The composite wing leading edge on Boeing’s Dreamliner features an integrated heating element that incorporates a sprayed metal conductive layer within the laminate stack.

Read MoreBeyond the Concorde: Next-generation SSTs

Civilian supersonic flight could begin a new era as aircraft developers position composites-intensive designs for market entry, particularly in the business-jet niche.

Read MoreCompetitive to the core

This new superyacht combines luxury innovations with energy-efficient construction, enabled by a new marine-grade balsa core.

Read MoreWatching a half-century of progress in composites

Looking back on my experience in the composites industry, from my first job in 1961 as a free-lance secretary to Brandt Goldsworthy to my last job as a free-lance writer for Composites Technology and High Performance Composites, gives me an uncommon perspective.

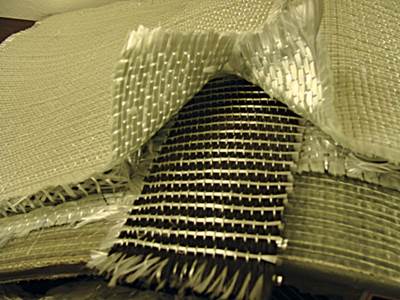

Read MoreWind Blade Manufacturing: Cost-efficient materials-based strategies

The wind blade’s four key elements — the root, the spar, the aerodynamic shell or fairing, and the surfacing system — have present unique manufacturing challenges that must be met with carefully selected composite material systems and molding strategies.

Read MoreWind Blade Manufacturing: Are thermoplastic composites the future?

In a market dominated by thermoset composites, some wind turbine blade manufacturers are actively pursuing new composite blade designs featuring faster-processing reinforced thermoplastics.

Read More